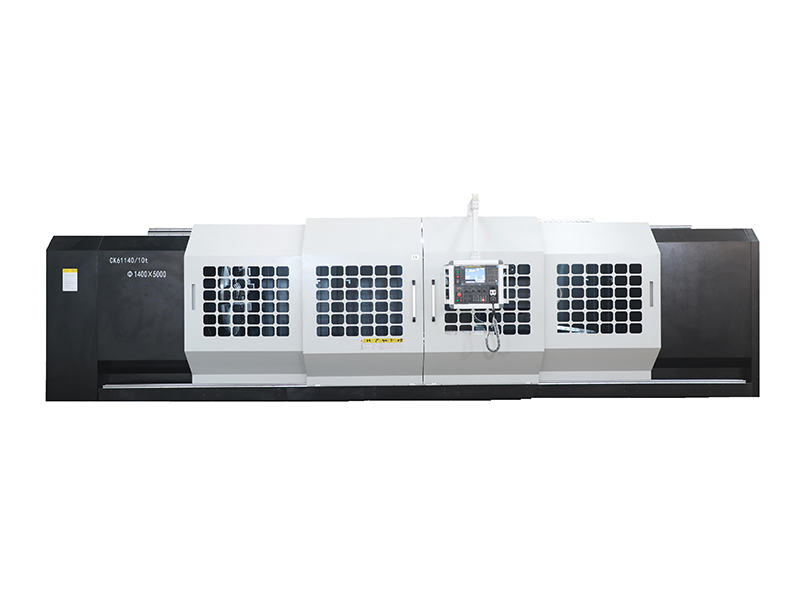

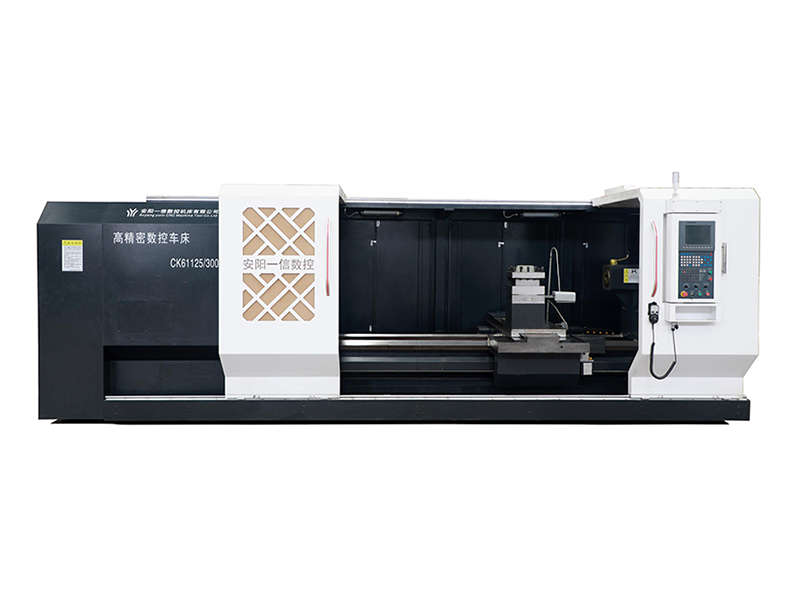

Product features:

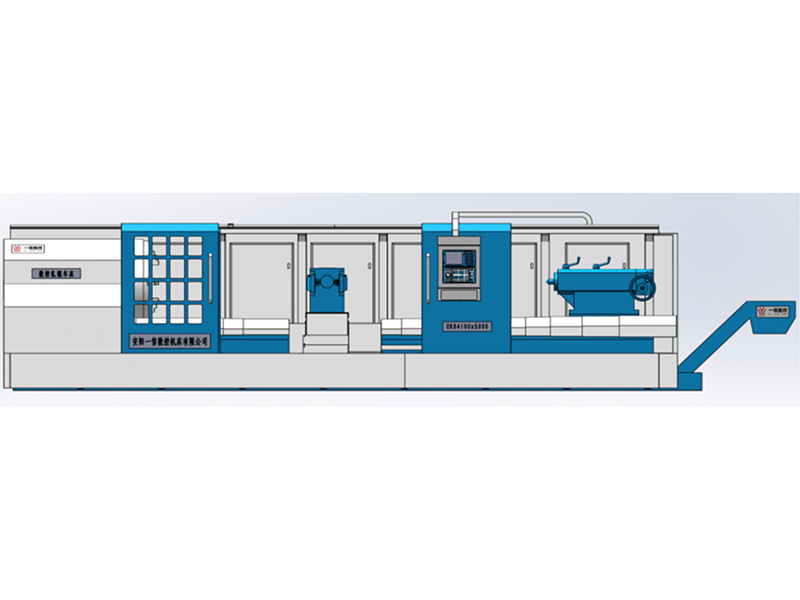

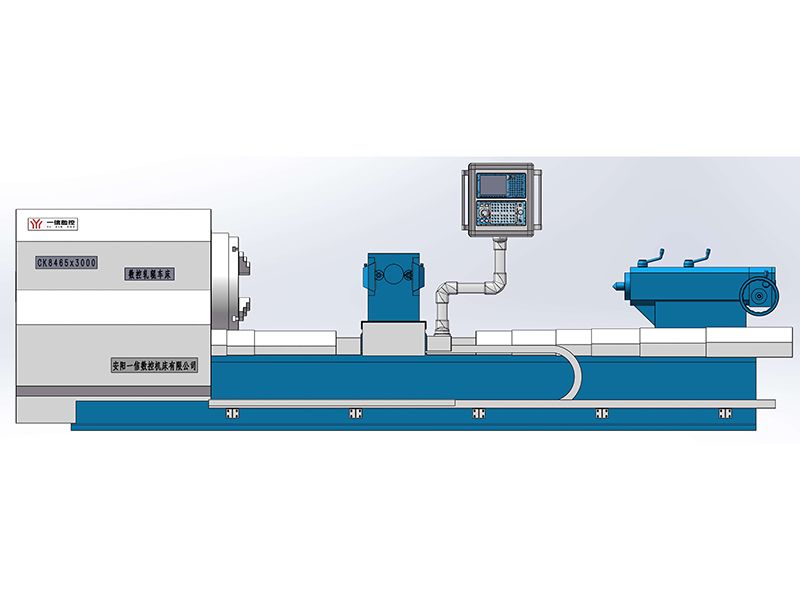

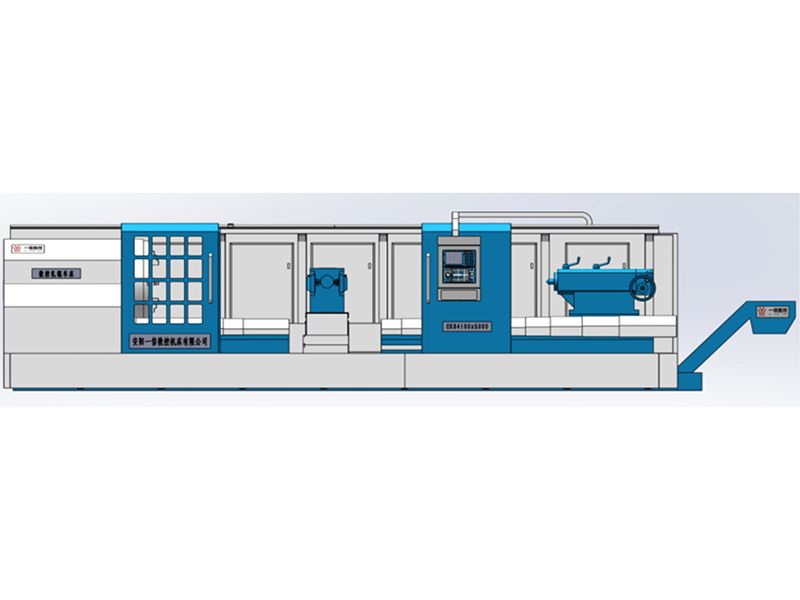

The standard configuration of the system is the Siemens 828D system from Germany.

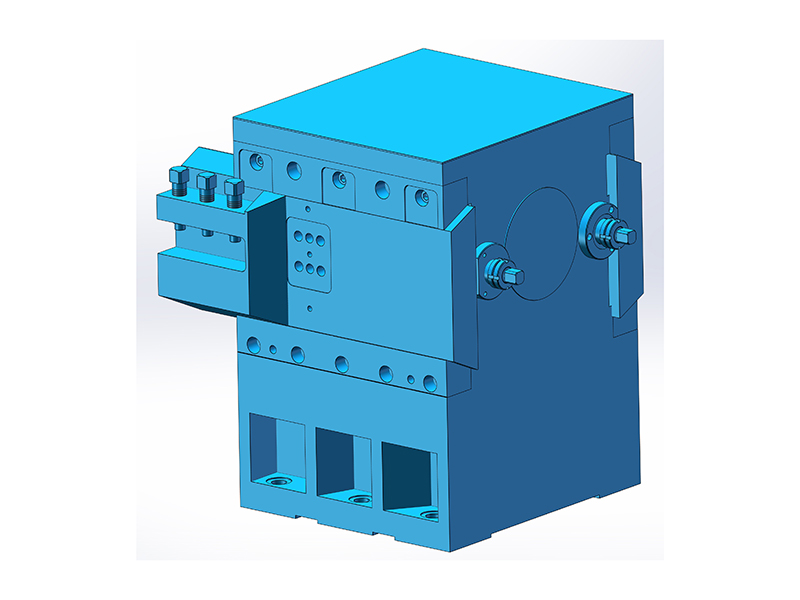

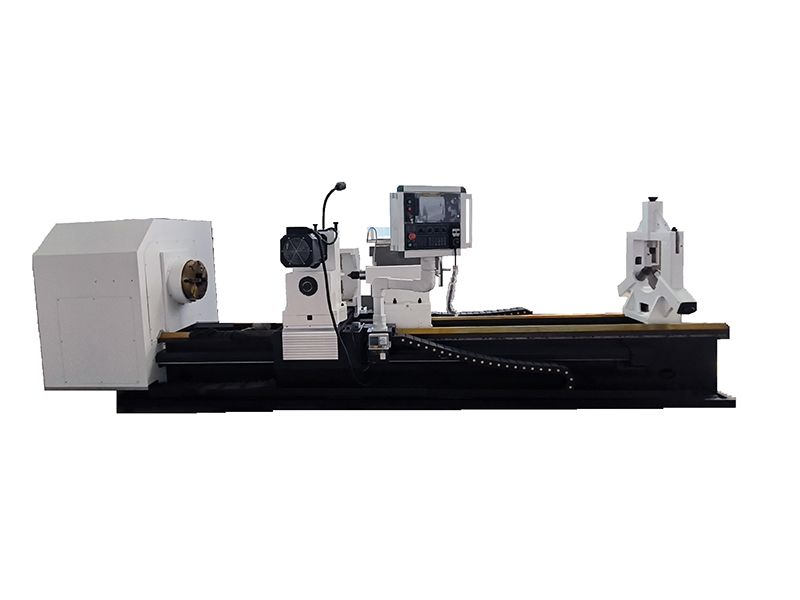

The machine tool bed adopts a four rail, linear rail, and rectangular composite structure. The main and auxiliary rails are separated, and the machine tool rails have a large span. The Z-direction feed system adopts heavy-duty linear roller rails and applies heavy-duty pre tensioning, which can withstand large loads, have high rigidity, and good precision.

The machine tool is equipped with a heavy-duty built-in rotating tailstock, with a large tailstock sleeve diameter and a stroke of 300mm. The top is MT-6, which has a sturdy structure and can withstand heavy cutting.

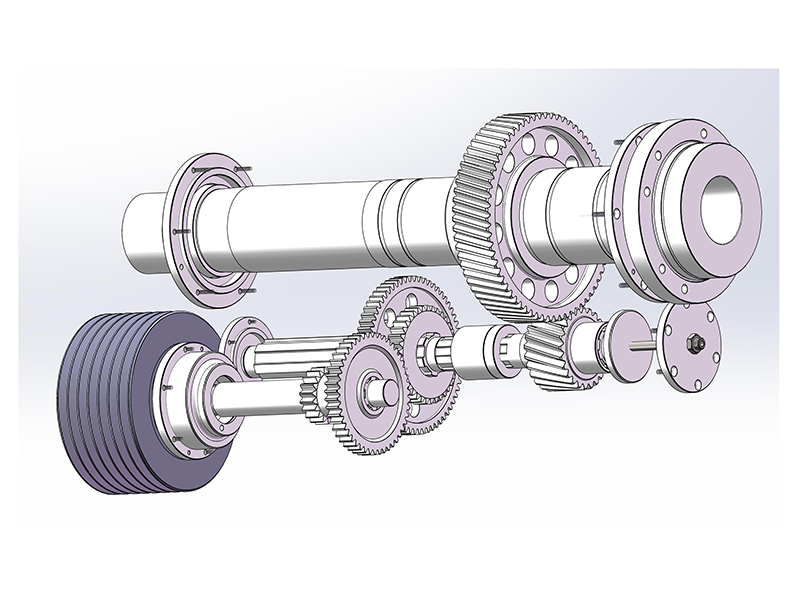

The spindle unit adopts hydraulic two speed variable speed, with a large spindle diameter and three-point support by precision heavy-duty bearings. The bearing accuracy adopts P4 level; The spindle motor adopts AC servo spindle motor, with low rated speed, high torque and moment of inertia; Combined with low-speed gear, it is suitable for rough machining of heavy parts. Combined with high-speed gear, it can improve the surface machining accuracy of parts and is suitable for precision machining, achieving the replacement of grinding with turning for some parts.

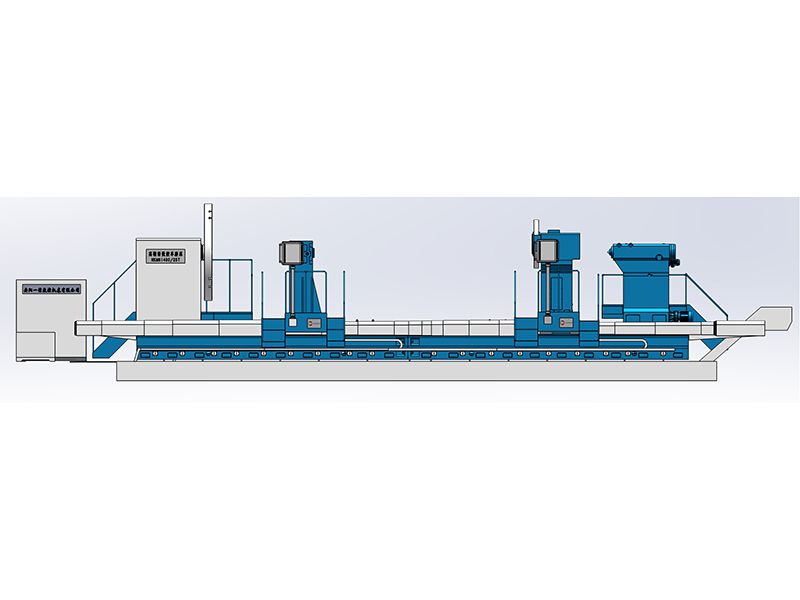

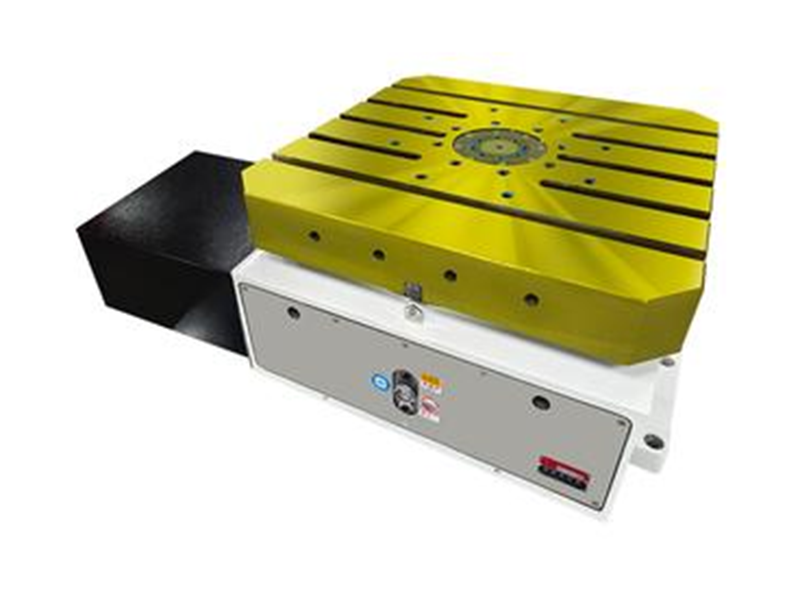

Modular design of machine tools allows for functional expansion. By using a quick change device and adding grinding heads, it can be expanded into an external cylindrical grinder; Equipped with a power tool holder, it can be expanded into a turning and milling composite center;

Mechanical arms can be added.

The machine tool electrical box is equipped with air conditioning as standard, and all main electrical control components are made of Schneider products from Germany, with low failure rate and maintenance costs, ensuring efficient machining of the machine tool.

Machine tool protection can be configured according to user needs, including simple protection, double door protection, full protection, etc;

According to the requirements of the user for processing parts, chip conveyors, cooling water tanks, etc. can be configured.

Item | Unit | CK8480 | CK84100 | CK84125 | |

Capacities | Swing over carriage | mm | 800 | 1000 | 1250 |

Max.length of workpiece | mm | 3000 - 10000 | |||

Max.tuininglength | mm | 3000 - 10000 | |||

Pan of guideway | mm | 1250 | |||

Max.weight of workpiece | t | 10t | 12t | 12t | |

Spindle | Spindle bore | mm | 100 | ||

Taper hole of spindle | Metric 140 | ||||

Chuck | mm | four claws 800 | four claws 1000 | four claws 1000 | |

Spindle nose | A2-15 | ||||

No.of spindle speeds | Hydraulic two gears | ||||

Range of spindle speeds | r/min | 5 ~300 | |||

Feed | Rapid speeds | m/min | 10/6 | ||

Max.travel | mm | 500 | |||

Max.travel | mm | 3000-10000 | |||

Tool post & Tailstock | Size of turret | mm | 300×300 | 350×350 | 380×380 |

Section of tool shank | mm | 40×40 | 50×50 | 50×50 | |

Turret working position | mm | 4 | |||

Dia.of tailstock quill | mm | 220 | 260 | 260 | |

Traval of tailstock quill | mm | 300 | |||

Taperhole of tailstock | mm | MT-6 | |||

Others | Workpiece accuracy | It7 | |||

Surface roughness | μm | Ra 0.8 | |||

Main power | kW | 45 | 55 | 55 | |

Width/Height | mm | 2900/1900(Simple protection) 3100/2300(Double door protection) | |||

CNC System | Siemens Germany 828D(Customizable according to requirements) | ||||