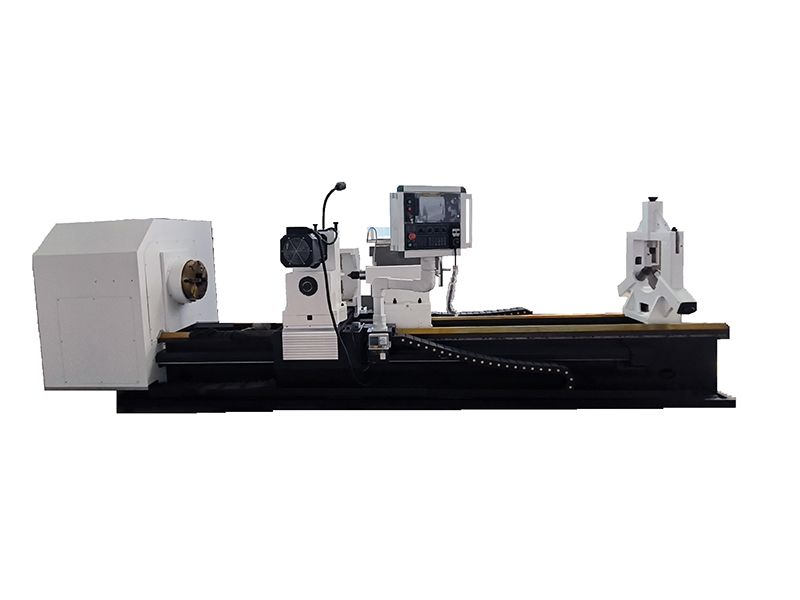

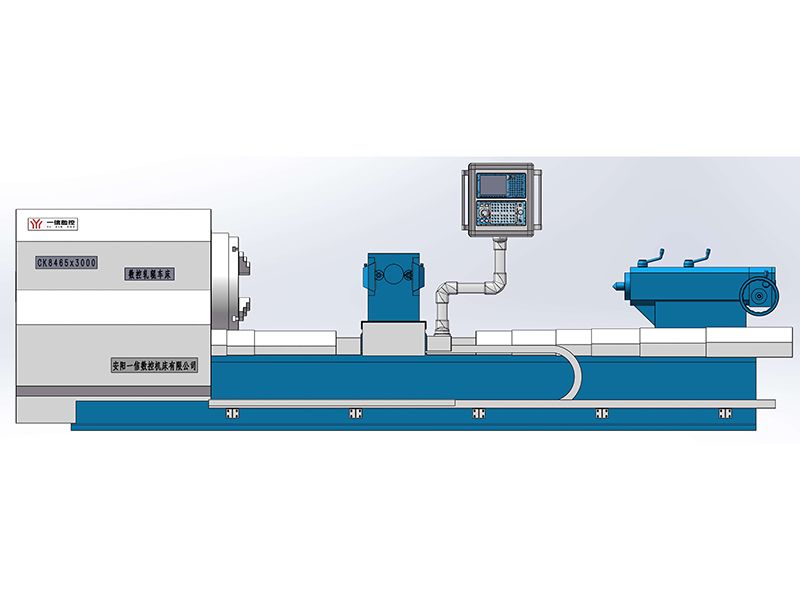

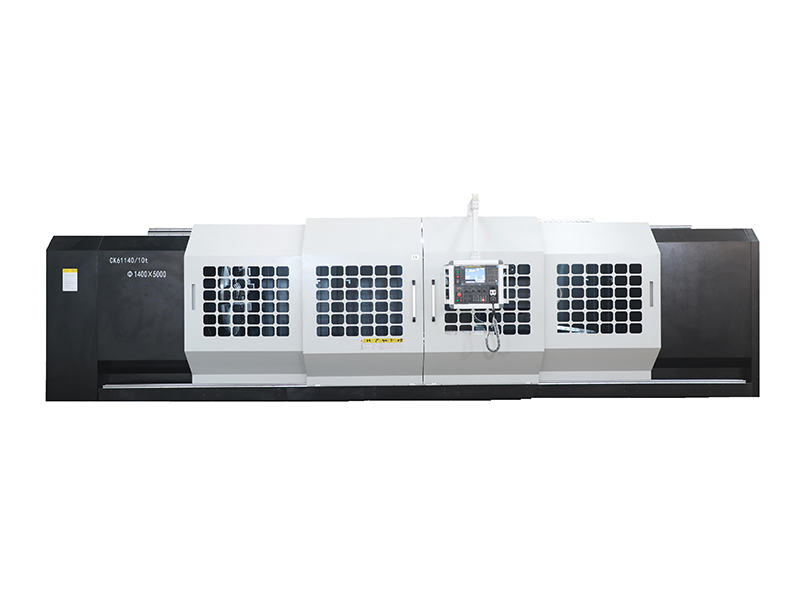

The main structure of the machine tool is an inverted T-shaped, movable column structure. The machine bed has a large span design, high rigidity and high strength. It can be clamped once to perform milling, drilling, reaming, boring, reaming, tapping and other processes on four surfaces. Modern machine tools and control concepts, compact structural design, ensure high efficiency and high precision processing requirements for single or small and medium batch products. It is suitable for complex processing of box parts.

Product features:

The system is equipped with Huazhong CNC 808DiM and 10.4-inch color display.

The spindle box adopts Taiwan Okada precision high-rigidity spindle unit with a rotation accuracy of 0.002mm, and the bearing adopts precision spindle bearings imported from Japan.

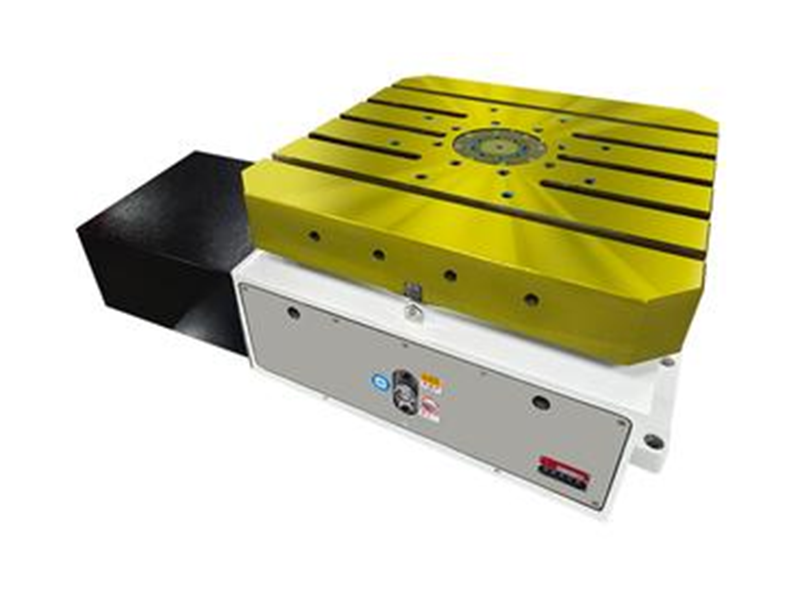

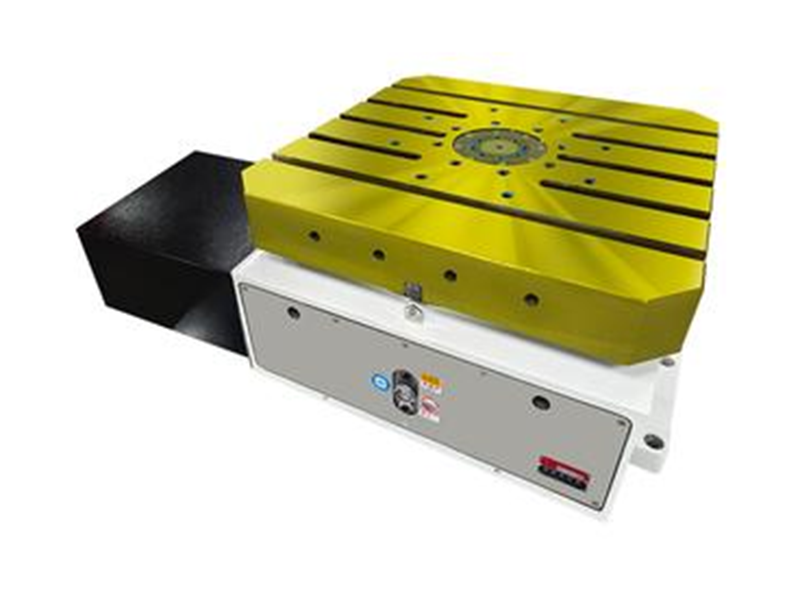

The turntable adopts a horizontal three-piece gear-type one-degree-one-minute precision turntable produced in Taiwan, with a table size of 1600×1600, rotation without lifting, and repeated positioning accuracy of 0.001mm.

The feed system adopts a new bearing support structure, standard Japanese THK high-precision large-load precision ball screw, accuracy level C3, X/Y axis adds precision 3 arc-minute planetary reducer, German KTR coupling and Taiwan Yingxi high-precision large-load locking nut to ensure high positioning accuracy and repeated positioning accuracy of the machine tool.

The machine tool adopts an integral casting bed, large span, wide guide rail, guide rail surface quenching and grinding, with good rigidity and shock absorption, which can ensure high-precision cutting processing. Equipped with Taiwan Okada 30-knife horizontal disc tool magazine, cylindrical cam segmentation structure, high precision and low failure rate; double-bearing separate tool arm, high concentricity, low tool change noise, electronic switch uses imported original parts, reliable quality and long service life. The maximum tool weight is 18kg, and the tool change time is 4.01 seconds.

The machine tool has a full protection design, which is novel and atmospheric. The chip conveyor adopts 4 screws and one chain, which is convenient for machine tool operation and maintenance. The layout of the electric box is reasonable, the operation and maintenance are convenient, and the degree of humanization is high.

| Specification | unit | TH1600 | |

| feed | Three axis travel(X/Y/Z) | mm | 2000×2000×1900 |

| Spindle end face to worktable center (front and rear) | mm | 450-2400 | |

| Spindle center to worktable (up and down) | mm | 100-2000 | |

| X/Y/Z-axis ball screw specifications | mm | 80/80/80 | |

| X/Y/Z axis guide rail type | Sliding guide rail, surface quenched | ||

| X/Y/Z/W axis feed motor torque | N.m | 48/48/48/35 | |

| workbench | Table size | mm | 1600×1600 |

| Maximum load capacity of workbench | Kg | 10000 | |

| T-shaped groove (groove x width x center distance) | mm | 7×22×200 | |

| Dividing angle | ° | 1° | |

| principal axis | Main spindle form | mm | Ø190-BT50 |

| Spindle motor power | Kw | 21 | |

| Rated speed of spindle motor | r/min | 1000 | |

| Spindle speed | r/min | 5-6000 | |

| Spindle motor torque | N.m | 200 | |

| Knife storage | Number of knives allowed | T | 30 |

| Maximum tool diameter | mm | Ø125 | |

| Neighbor Empty Knife | mm | Ø200 | |

| Maximum tool length | mm | 400 | |

| Maximum allowable weight of cutting tools | Kg | 18 | |

| Tool change time | sec | 4 | |

| speed | Fast moving speed(X/Y/Z) | m/min | 10 |

| feed rate(X/Y/Z) | mm/min | 1-5000 | |

| Workbench speed | r.p.m | 3 | |

| accuracy | positioning accuracy | mm | ±0.025 |

| Repetitive positioning accuracy | mm | 0.016 | |

| other | Total capacity of machine tool power supply | kw | 65 |