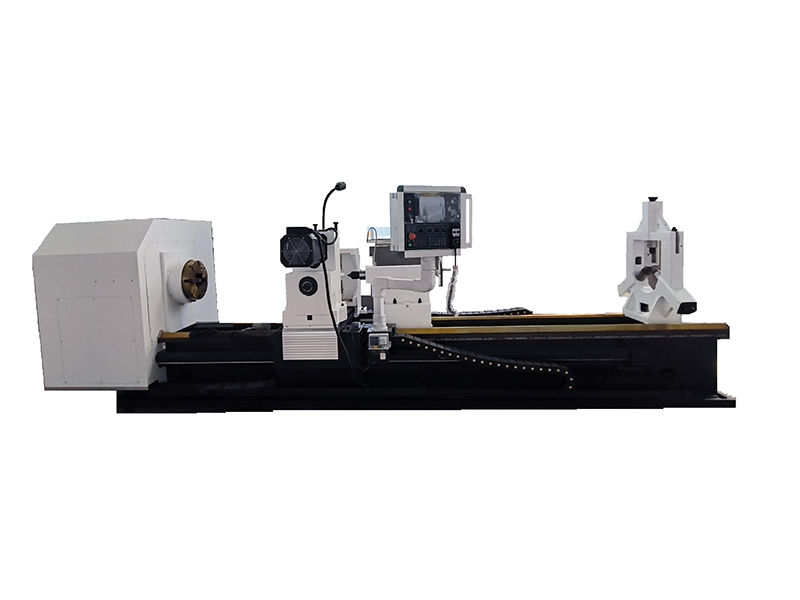

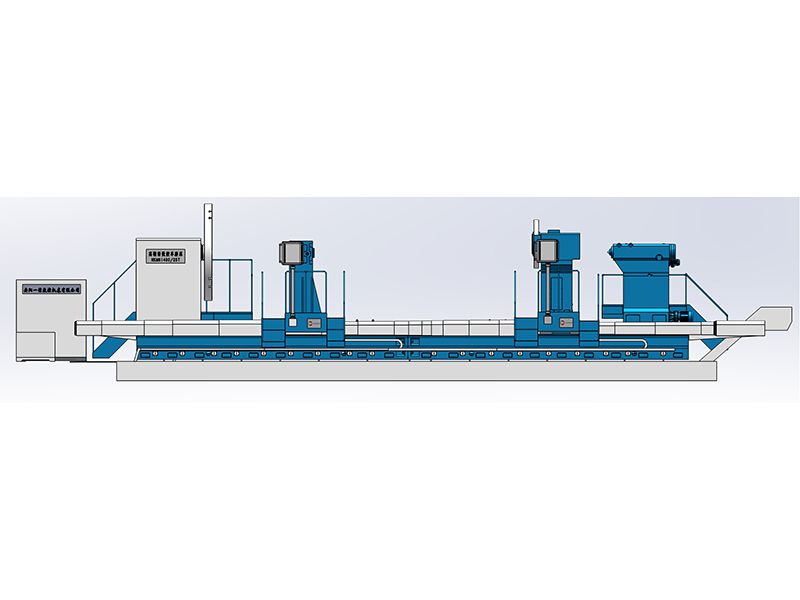

CXK350 series CNC screw milling machine CXK350 series irregular CNC screw milling machine is a specialized machine designed for processing various irregular screws such as equal lead, variable lead, gradient lead, equal groove depth, and variable groove depth. This product aims to pursue high speed, high precision, and high efficiency, and uses finite element analysis and other methods to analyze, research, design, and produce special-shaped CNC screw milling machines based on high-speed, precision, heavy-duty spindle design and manufacturing technology, high-power C-axis design technology, precision feed drive technology, CNC servo parameter optimization technology, thermal deformation control and compensation technology, reliability technology, etc. It can be processed individually or in batches. High efficiency, simple operation, safe and reliable.

Product features:

The standard configuration of the system is the Wide Number 980TDI system, and other systems can also be configured according to user needs.

The guide rail adopts a "one mountain, one flat" structure, with a large span and good rigidity.

The milling spindle adopts an AC servo spindle motor, which can enable the milling cutter to achieve infinite speed and a wide speed range. The milling head can manually adjust the angle according to the requirements of the workpiece.

It can achieve multi axis linkage machining, and can complete multiple processes of the screw with one clamping. It can change the lead and diameter, reduce auxiliary time, and greatly improve machining efficiency compared to traditional screw milling machines.

According to the shape and processing requirements of the screw, cutting parameters and processing paths can be automatically optimized to increase cutting speed and feed rate, and shorten processing time.

The feed system of the machine tool adopts a high rigidity bearing support structure, equipped with high-precision high load ball screws, and the Z-axis is equipped with a precision 3-arc planetary gearbox, German Kaitian coupling, and Taiwan Yingxi high-precision high load locking nut to ensure the accuracy and stability of the machine tool.

The machine tool adopts an integral cast bed body, and the guide rail surface is quenched and ground, which has good rigidity and shock absorption, ensuring high-precision cutting processing.

The machine tool adopts a simple protective design, novel and atmospheric, reasonable electrical box layout, convenient operation and maintenance, and high degree of humanization.

The machine tool electrical box is equipped with air conditioning as standard, and the main electrical control components are all domestic and foreign famous brand products, with low failure rate and low maintenance cost, ensuring efficient machining of the machine tool.

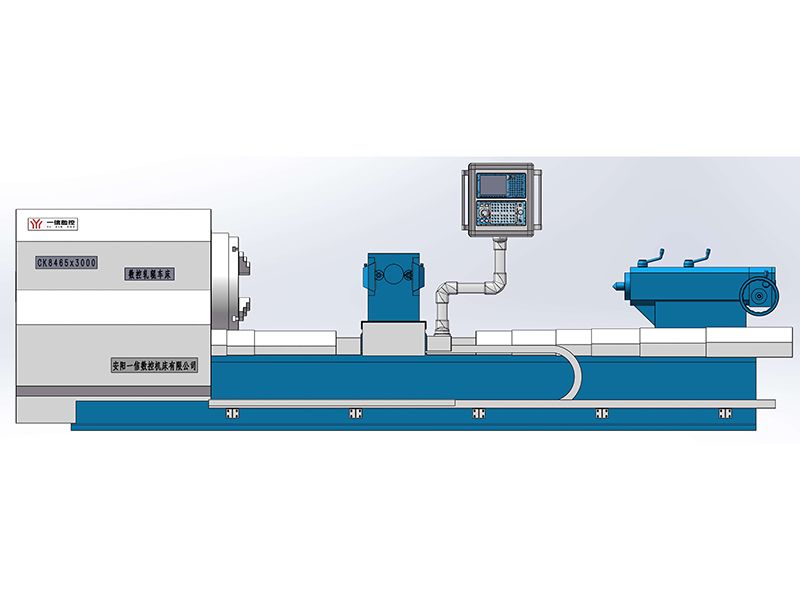

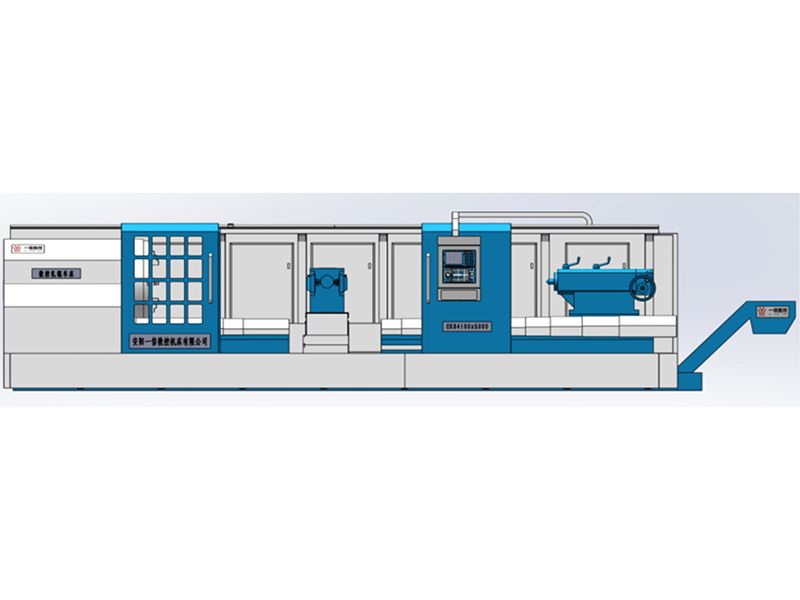

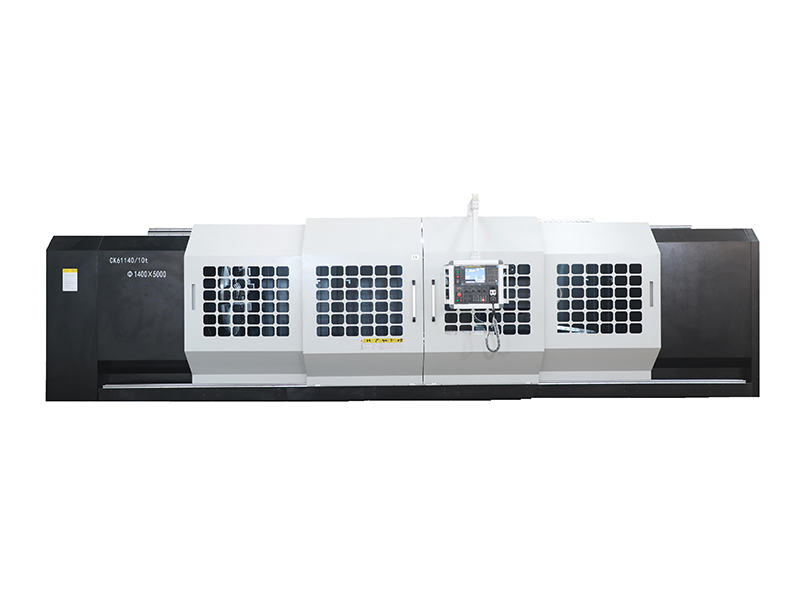

MODEL | CXK350 |

Two top workpiece length | 2000,3000,4000,5000,6000 |

Maximum machining length of the machine tool | 1700,2700,3700,4700.5700 |

Maximum machining diameter | Φ50-350 |

Bed width | 755 |

Machine tool center high | 500 |

Spindle speeds | 0.1-9(无级) |

Spindle hole | Φ100 |

Type of milling cutter | BT50 |

Milling speed ratio | 1:4 |

The milling head can adjust the angle | ±30° |

Miling header spindle speeds | 50-1000r/min |

Motor Power of milling header | 11kW |

C-axis servo-motor torque | 22 |

C speed of spindle | 0-5r/min |

C axis positioning accuracy | 10角秒 |

X-axis servo-motor torque | 22 |

X axis fast shift speed | 10 |

Z-axis servo-motor torque | 28 |

Z axis fast shift speed | 8 |

Tail seat sleeve diameter | 100 |

Top taper of the seat sleeve | MT-5 |

Maximum stroke of sleeve | 250 |

Card plate specifications | K11-400C |

Numerical control system | 广数 980TDI |

Axis | X、Z、C |