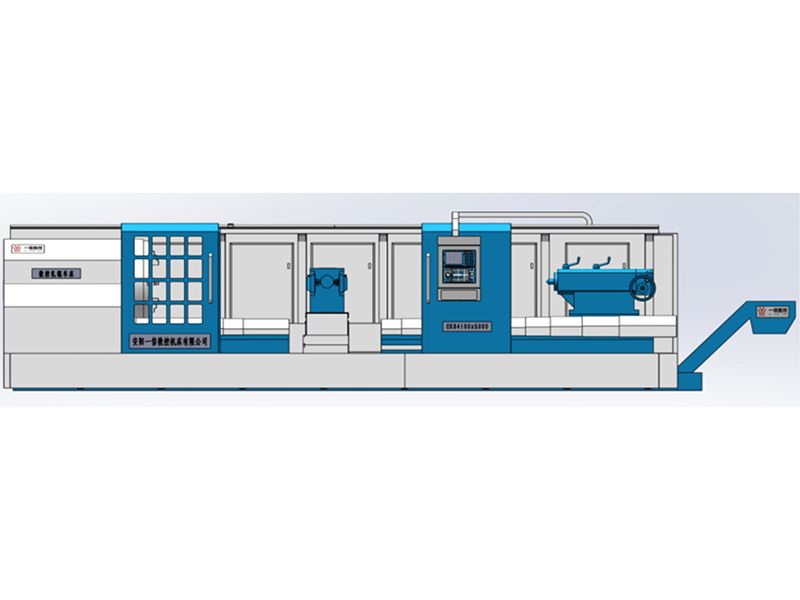

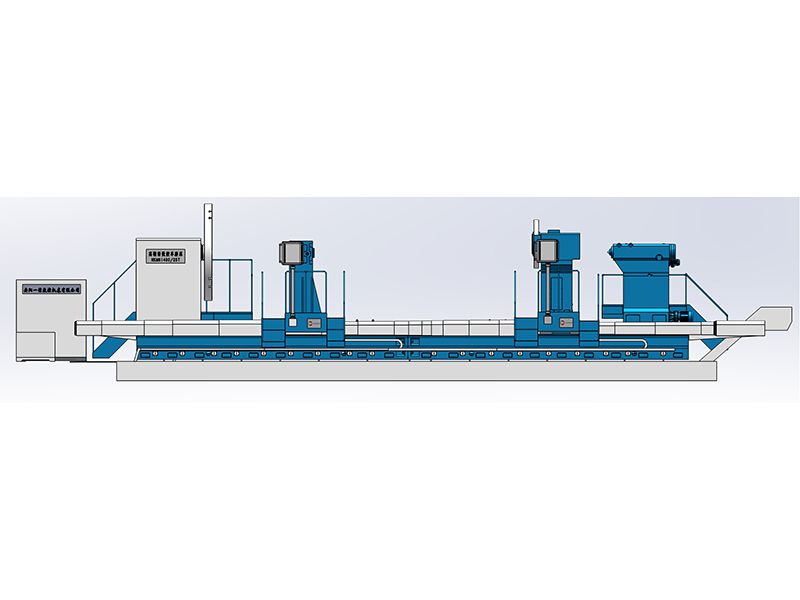

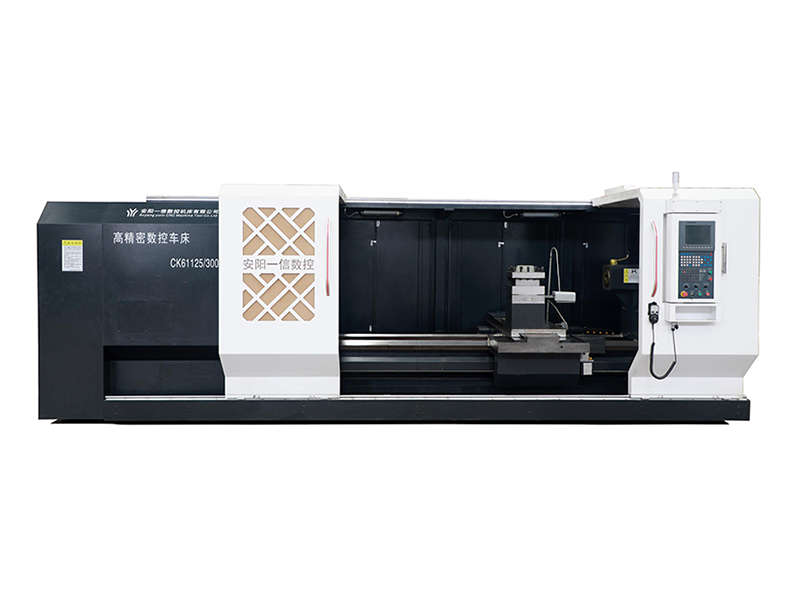

The heavy-duty CNC lathe grinder is a heavy-duty CNC lathe grinder designed and produced by our company based on the current processing technology of medium and large parts, combined with advanced technologies of heavy-duty CNC roll lathes and CNC roll grinders at home and abroad, with the goal of pursuing safety, reliability, and cost savings. Using modern CNC machine tool design methods as a means, we analyze and research high-speed precision spindle design and manufacturing technology, precision feed drive technology, CNC servo parameter optimization technology, thermal deformation control and compensation technology, reliability technology, etc.

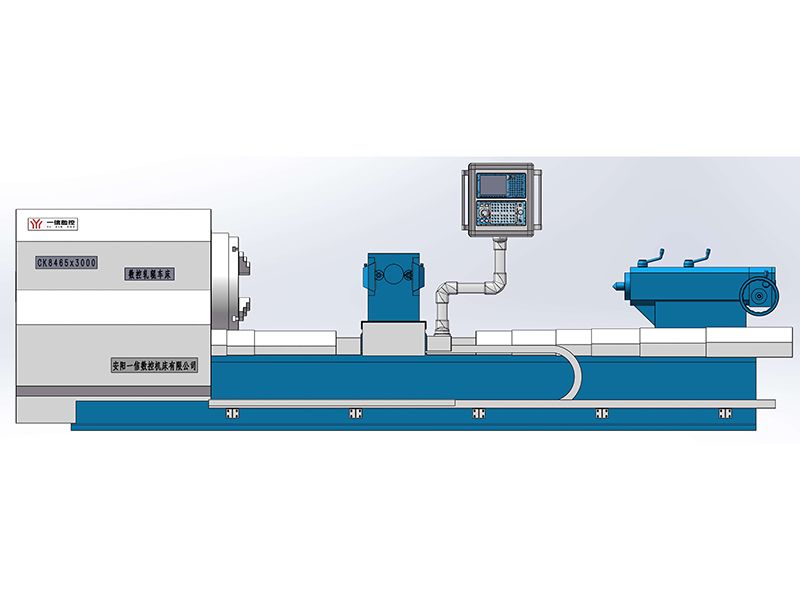

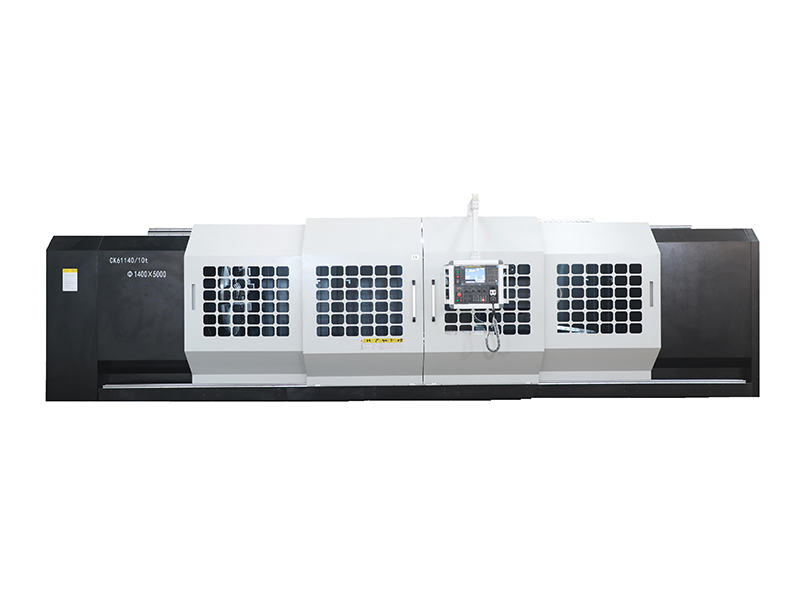

This equipment is mainly used for processing shaft and roll parts in plastic machinery, steel rolling, papermaking machinery, and other special industries. It is suitable for cutting tools such as high-speed steel, hard alloy, cubic boron nitride, diamond, etc. It is suitable for rough and fine machining of black metal, non-ferrous metal, and some non-metallic parts. It can turn the cylindrical surface, conical surface, end surface, groove, and circular arc surface of the parts, and grind the outer circle of rotary parts.

Product features:

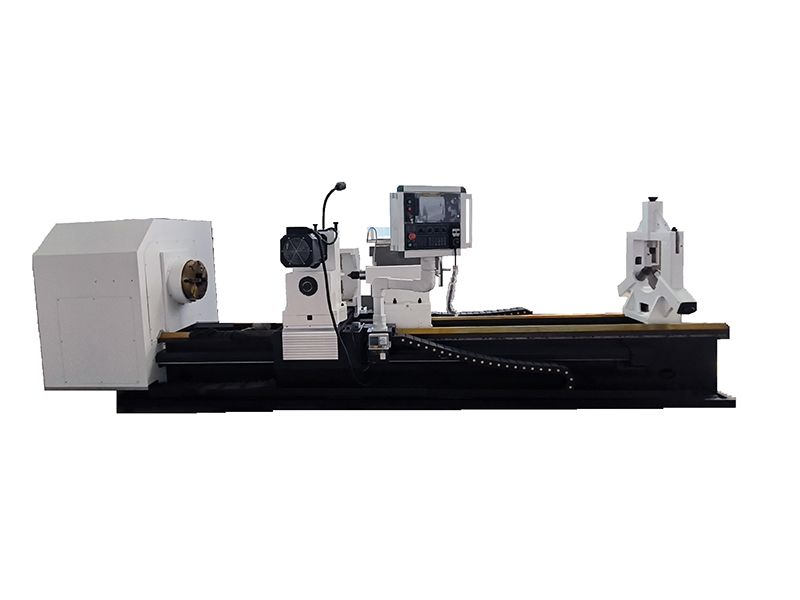

The standard configuration of the system is Siemens 828D from Germany, with dual operation boxes and dual screen displays.

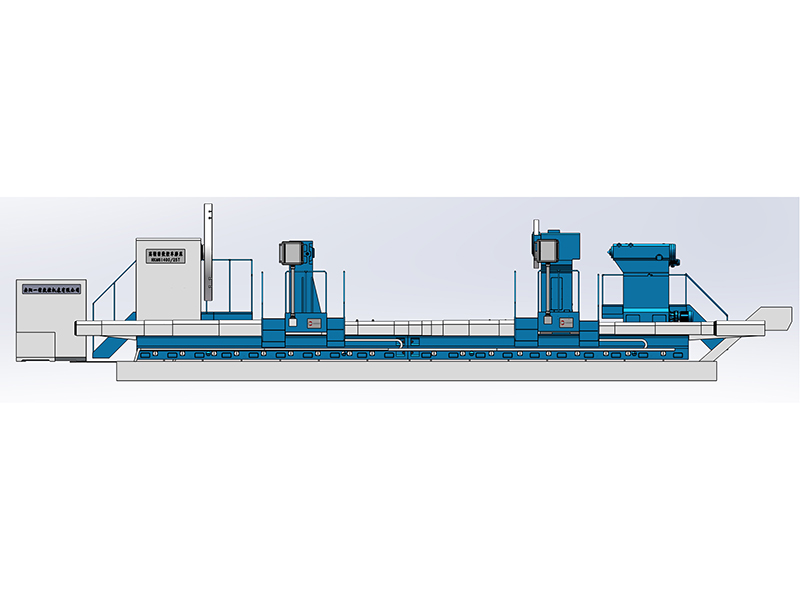

The machine tool bed adopts a double bed structure, with a large span for a single bed and a span of 4020mm for two beds. It can withstand large loads, has high rigidity, and good precision.

The machine tool is equipped with a heavy-duty built-in rotating tailstock, with a large tailstock sleeve diameter, a stroke of 300mm, and a top taper of metric 100. The structure is sturdy and can withstand heavy cutting.

The machine tool spindle adopts hydraulic two speed variable speed, with a large spindle diameter and three-point support by precision heavy-duty bearings. The bearing accuracy adopts P4 level;

The spindle motor adopts Siemens 95Kw AC servo spindle motor from Germany, which has high torque and moment of inertia;

When paired with low-speed gear, it is suitable for rough machining of heavy parts. When paired with high-speed gear, it can improve the surface machining accuracy of parts and is suitable for precision machining.

The machine tool adopts a dual tool holder structure, one for turning and the other for grinding. The grinding tool holder spindle adopts a static pressure spindle, which has good rigidity and high rotation accuracy, suitable for precision grinding processing.

The machine tool electrical box is equipped with air conditioning as standard, and all main electrical control components are made of Schneider products from Germany, with low failure rate and maintenance costs, ensuring efficient machining of the machine tool.

Modular design of machine tools allows for functional expansion. By using a quick change device and equipped with a power tool holder, it can be expanded into a turning and milling composite center; Mechanical arms can be added.

Item | Unit | HKM61400/25 | |

Capacities | Swing over bed | mm | 4000 |

Swing over carriage | mm | 3500 | |

Max.length of workpiece | mm | 10000 | |

Max.weight of workpiece | t | 25 | |

Taper hole of spindle | 公制140 | ||

Chuck | mm | 四爪2500 | |

Spindle nose | A2-15 | ||

No.of spindle speeds | 液压两挡 | ||

Range of spindle speeds | r/min | 1 ~100 | |

Feed | Rapid speeds | m/min | 10/5 |

Max.travel | mm | 10000 | |

Max.travel | mm | 1200 | |

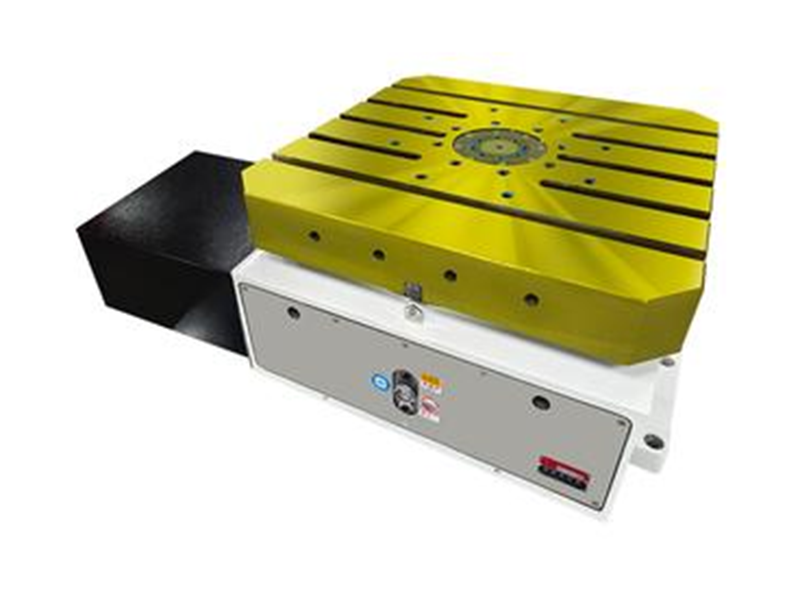

Tool post & Tailstock | Size of turret | mm | 框式刀架 |

Section of tool shank | mm | 70 ×60 | |

Turret working position | mm | 2 | |

Dia.of tailstock quill | mm | 300 | |

Traval of tailstock quill | mm | 300 | |

Taperhole of tailstock | mm | 公制 100 | |

Others | Main power | kW | 210 |

Length | mm | 21000 | |

Width/Height | mm | 7400/4300 | |

CNC System | 西门子828D(可根据要求定制) | ||