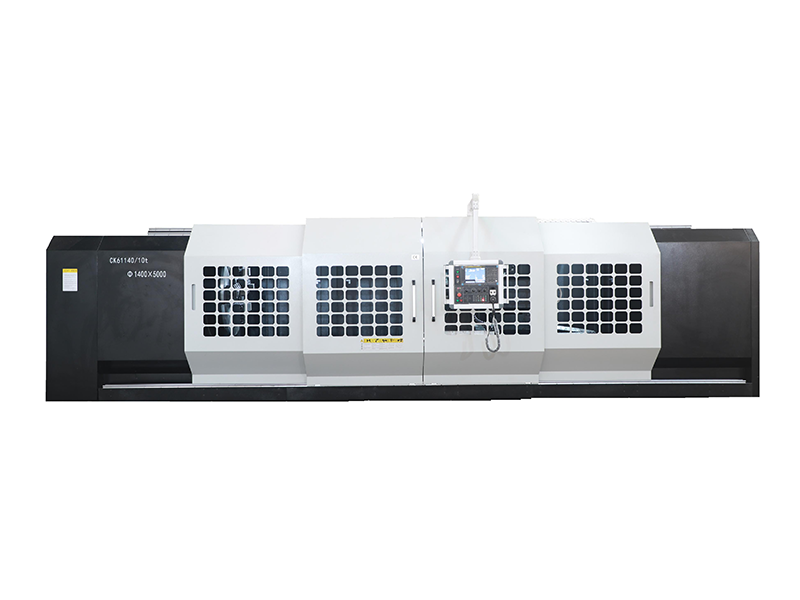

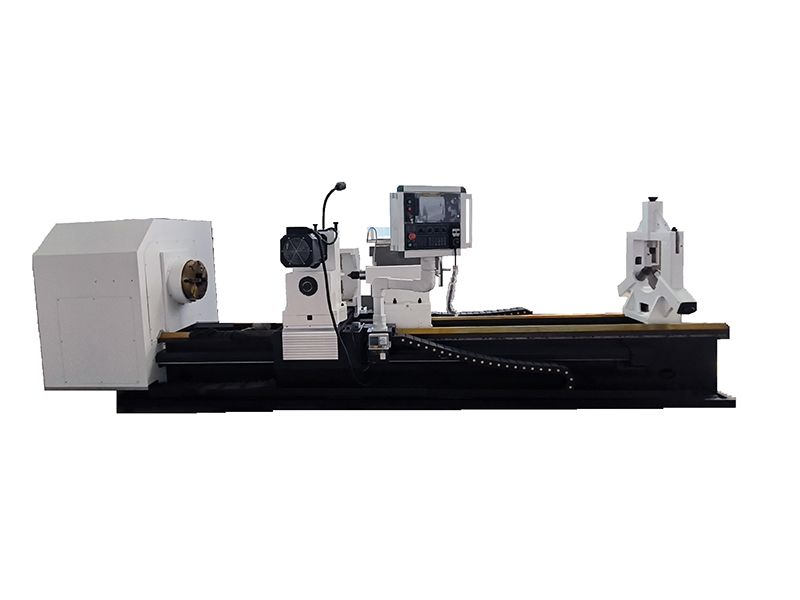

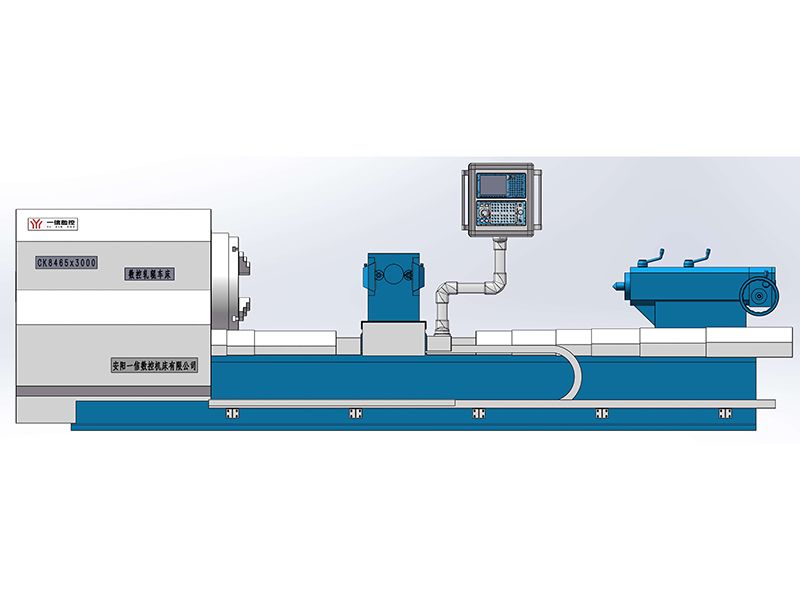

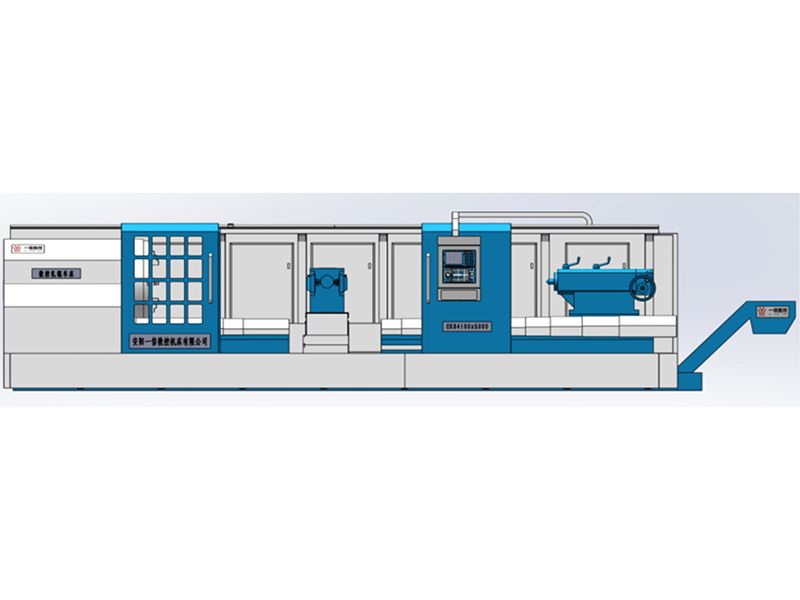

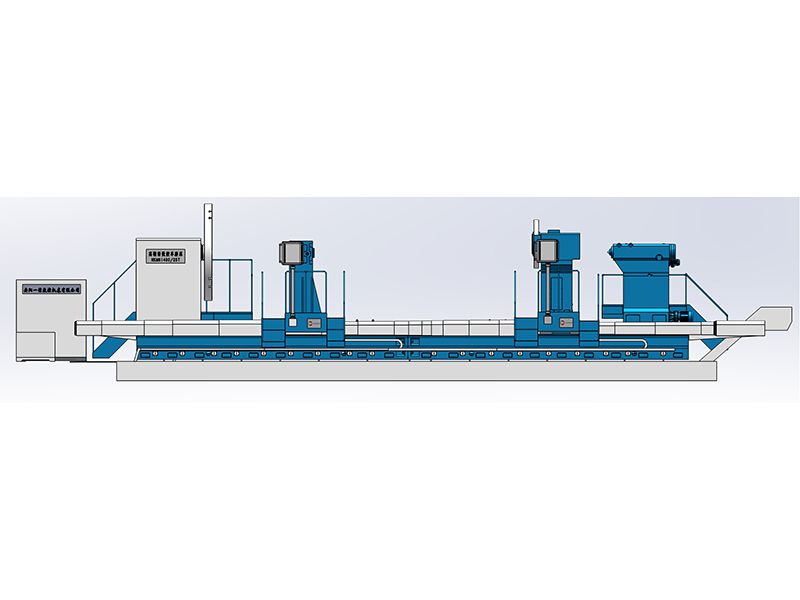

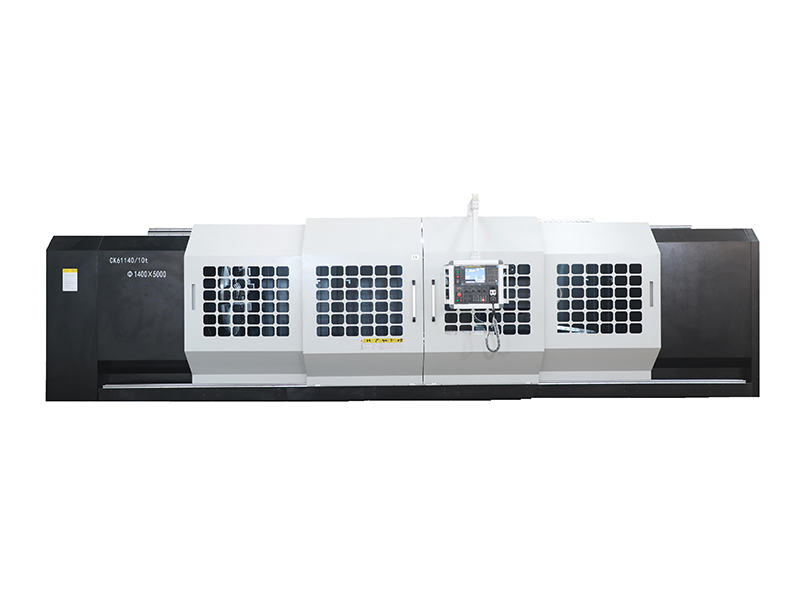

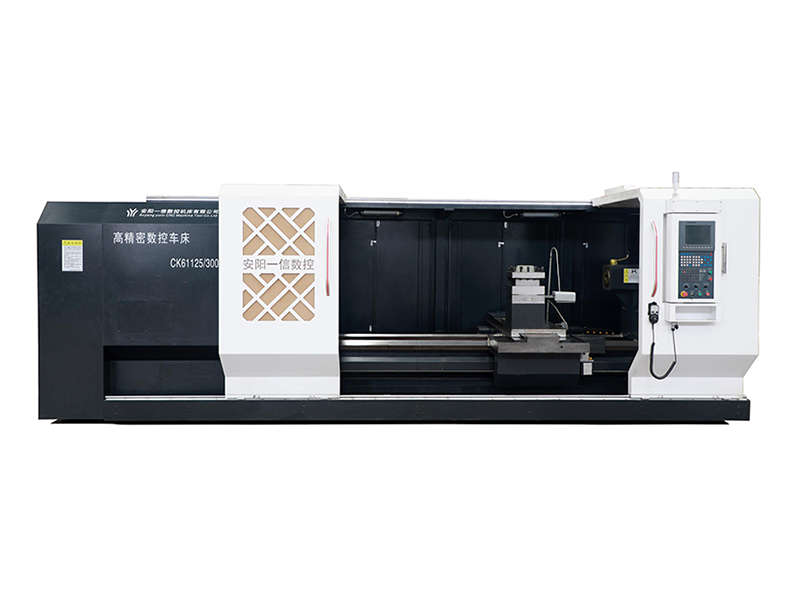

This machine tool is a heavy-duty semi-closed-loop controlled CNC lathe developed according to the special needs of users and the difficulties in user processing. The machine tool adopts open protection, and it is convenient and quick to clamp parts. It is suitable for processing various complex-shaped shafts, sleeves, and disc parts, such as turning internal and external cylindrical surfaces, conical surfaces, arc surfaces, end faces, grooving, chamfering, and threading.

The power turret can be optionally upgraded to a turning and milling center to adapt to the processing of various complex parts. It can also be equipped with a steady rest, a bracket, etc.; and other CNC systems can be selected.

Product features:

The system is equipped with Siemens system as standard.

The guide rail is a "one mountain and one flat" structure, and the guide rail span is 1100mm.

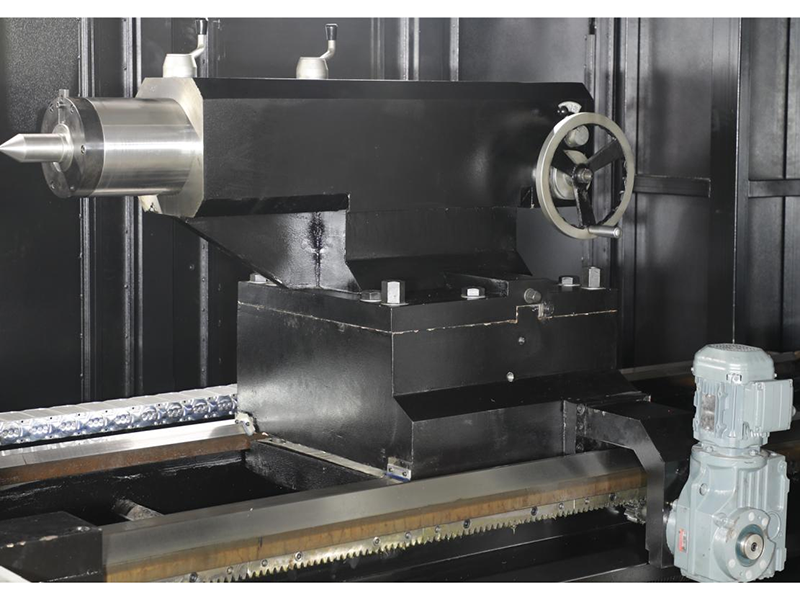

The heavy-duty built-in rotary tailstock has a tailstock sleeve diameter of Φ260mm and a stroke of 300mm.

The spindle box adopts a precision spindle and is equipped with P4-level high-precision high-speed spindle bearings as standard.

The machine tool speed change system adopts hydraulic automatic two-speed speed change; the low-speed gear achieves low-speed and high-torque output to achieve heavy cutting; the high-speed gear achieves constant linear speed and high-speed precision cutting, and some parts are replaced by turning instead of grinding, with a roughness of 0.8.

The feed system adopts a new bearing support structure, with high-precision and high-load precision ball screws as standard, and the Z-axis is equipped with a precision 3-arc-minute planetary reducer, a German KTR coupling and a Taiwan Yingxi high-precision and high-load locking nut.

The machine tool adopts an integral casting bed, and the guide surface is quenched and ground. It has good rigidity and shock absorption, which can ensure high-precision cutting.

The machine tool adopts simple protection, novel and elegant, reasonable layout of the electrical box, convenient operation and maintenance, and high degree of user-friendliness.

| Item | Unit | CK61160 | CK61180 | CK61200 | |

| Capacities | Swingoverbed | mm | 1600 | 1800 | 2000 |

| Swingovercarriage | mm | 1200 | 1400 | 1600 | |

| Max.lengthofworkpiece | mm | 2000/3000/5000/6000 | |||

| Max.tuininglength | mm | 1800/2800/4800/5800 | |||

| Panofguideway | mm | 1100 | |||

| Max.weightofworkpiece | t | 16 | |||

| Spindle | Spindlebore | mm | 100 | ||

| Taperholeofspindle | Metric 140 | ||||

| Chuck | mm | Four Claws 1250 | |||

| Spindlenose | A215(1:4;φ285.775mm) | ||||

| No.ofspindlespeeds | Two speed stepless | ||||

| Rangeofspindlespeeds | r/min | 5~320 | |||

| feed | Rapidspeeds | m/min | May 5th | ||

| Max.travel | mm | 850 | |||

| Tool post & Tails tock | Sizeofturret | mm | 380×380 | ||

| Sectionoftoolshank | mm | 50×50 | |||

| Turretworkingposition | mm | 4 | |||

| Dia.oftailstockquill | mm | 260 | |||

| Travaloftailstockquill | mm | 300 | |||

| Taperholeoftailstock | mm | 公制80# | |||

| Others | Workpieceaccuracy | It7 | |||

| Surfaceroughness | μm | Ra1.6 | |||

| Mainpower | kW | 45 | |||

| Length | mm | 5300/6300/8300/9300 | |||

| Width/Height | mm | 3100/2700(CK61160) | |||

| CNCSystem | Taiwan's new generation 21TA-E (can be customized according to requirements) | ||||