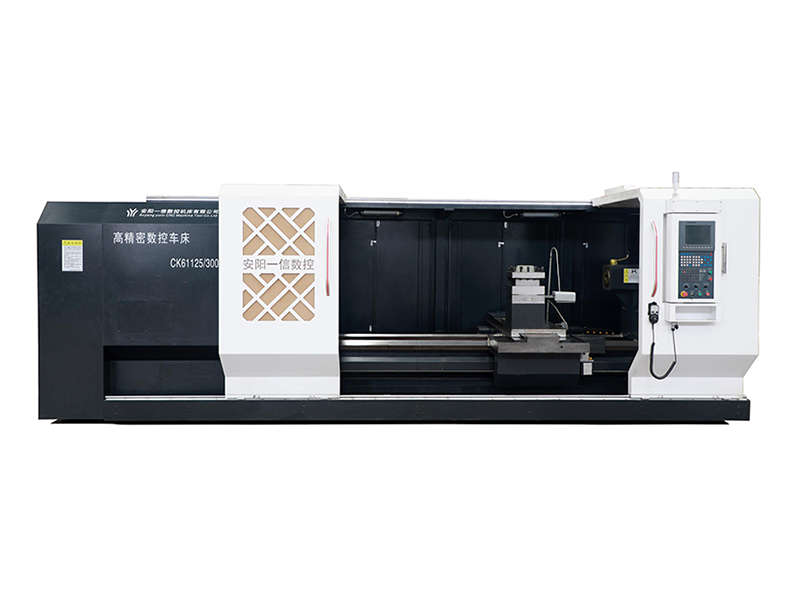

This series of machining centers are small and medium-sized machine tools. After one clamping, the workpiece can automatically and continuously complete multiple processes such as milling, drilling, boring, expanding, reaming, countersinking, and tapping. The machine tool is suitable for multi-variety small and medium-sized batch processing of complex parts such as small and medium-sized boxes, plates, discs, valves, shells, molds, etc. It is widely used in precision parts, 5G products, hardware, auto parts, and medical equipment industries. The machining center is easy to clamp, has strong process adaptability, high processing efficiency, low scrap rate, good finished product consistency, and can reduce the requirements for workers' technical proficiency.

Product features:

l The system is equipped with Huazhong CNC system 808DiM and 10.4-inch color display.

l The three-axis guide rail and lead screw protection cover is a fully enclosed protection, which effectively protects the guide rail and lead screw and reduces the damage caused by iron chips, oil stains, dust and cutting fluid.

l The integrated box structure design of the saddle significantly improves its support rigidity.

l The base is designed with transfer support feet, which is convenient for forklift transportation.

l The base bears the cutting force in the spindle direction. In order to reduce the support span of the front and rear feet and enhance the rigidity of the base support, the foot support is added between the front and rear feet to reduce the deformation of the base.

l The machine tool is equipped with a standard hat-shaped tool magazine, which is convenient for tool change. Other types of tool magazines can also be configured according to user needs.

l The machine tool is equipped with Taiwan University and Okada high-speed spindle units with high rotation accuracy and fast speed.

lThe machine tool guide rail adopts a two-wire and one-hard structure, with high fast moving speed, good machine tool rigidity, high precision stability, and is suitable for the processing of rough and fine parts.

lThe machine tool coupling adopts German Kaitian or Japanese Miki to ensure the transmission accuracy of the three axes.

lThe machine tool electrical box is equipped with air conditioning as standard, and the low-voltage electrical components are produced by Schneider of Germany, with low failure rate and maintenance-free.

lThe machine tool has a full protection design, which is novel and atmospheric, easy to operate and maintain the machine tool, the electrical box layout is reasonable, the operation and maintenance are convenient, and the degree of humanization is high.

| Specification | unit | VMCL850 | VMCL970 | VMCL1580 |

| X/Y/Z axis travel | mm | 800/500/500 | 1100/650/750 | 1500/800/800 |

| Distance from spindle nose to worktable | mm | 110—610 | 95—845 | 85—885 |

| Distance from spindle center to column surface | mm | 560 | 700 | 865 |

| Spindle speed | rpm | belt 8000 | belt 8000 | belt 8000 |

| Spindle nose taper | BT40/150 | BT40/150 | BT50/155 | |

| Tool change time | second | 2 | 2 | 4 |

| Number of cutting tools | pc | 16 | 20 | 24 |

| Maximum tool weight | kg | 7 | 7 | 7 |

| Spindle motor power | kw | 7.5/11 | 7.5/11 | 15 |

| X/Y/Z motor torque | N.m | 2010/12/12 | 20/20/20 | 28/28/28 |

| Table size | mm | 1000×500 | 1200×650 | 1700×810 |

| Maximum load capacity of workbench | kg | 500 | 800 | 1500 |

| T-shaped groove (groove, width, center distance) | mm | 5×18×90 | 5×18×120 | 5×18×147.5 |

| X-axis rapid displacement | m/min | 24 | 24 | 24 |

| Y-axis rapid displacement | m/min | 24 | 24 | 24 |

| Z-axis rapid displacement | m/min | 18 | 16 | 14 |

| positioning accuracy | mm | ±0.016 | ±0.016 | ±0.016 |

| repeatability | mm | ±0.008 | ±0.008 | ±0.01 |

| Numerical Control System | Huazhong CNC | Huazhong CNC | Huazhong CNC | |

| machine weight | kg | 5000 | 5200 | 8500 |

| power requirement | kva | 20 | 25 | 35 |

| Water tank capacity | l | 250 | 250 | 250 |

| Air pressure source | kg/cm2 | 6 | 6 | 6 |