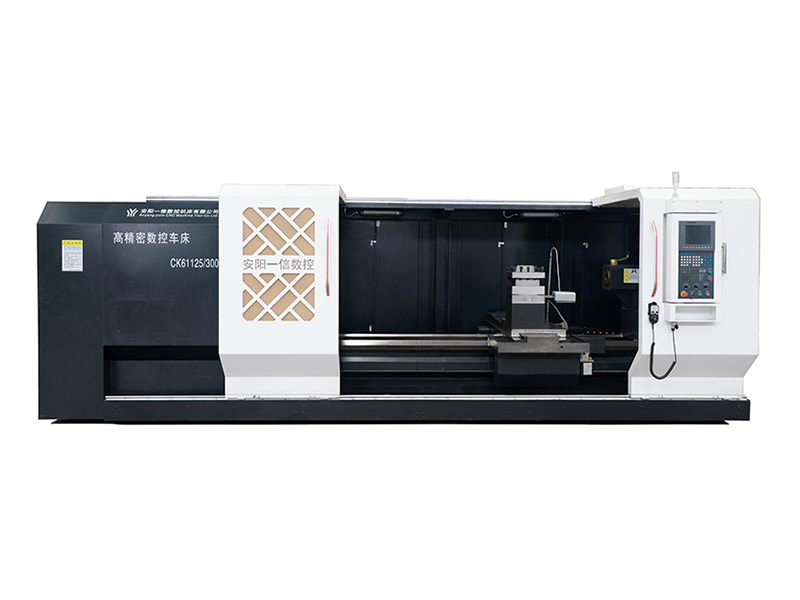

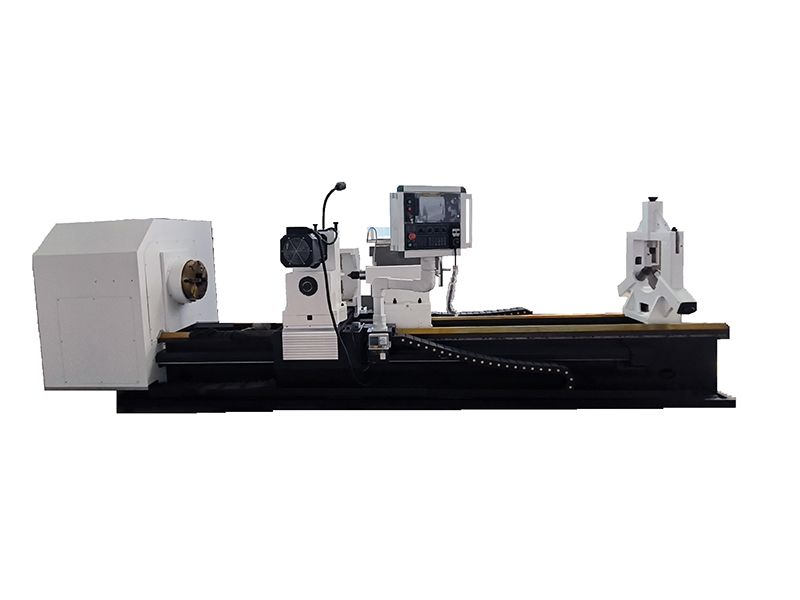

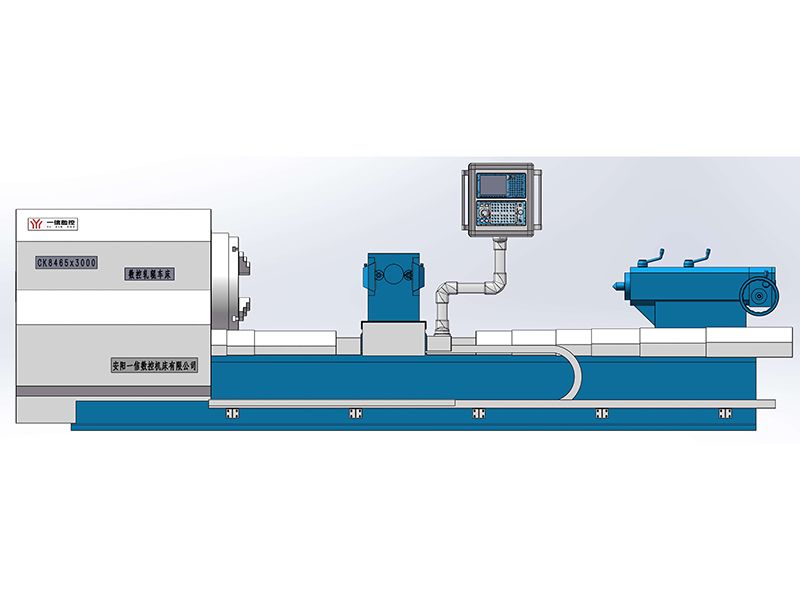

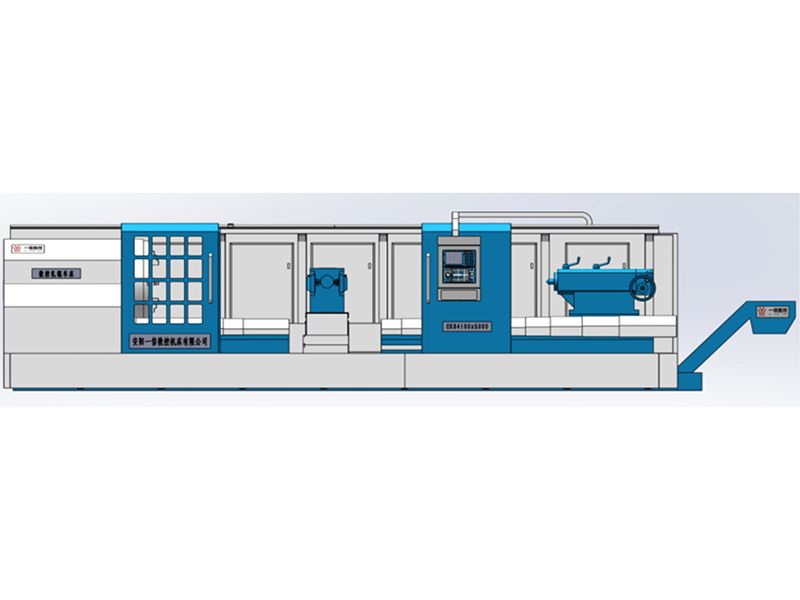

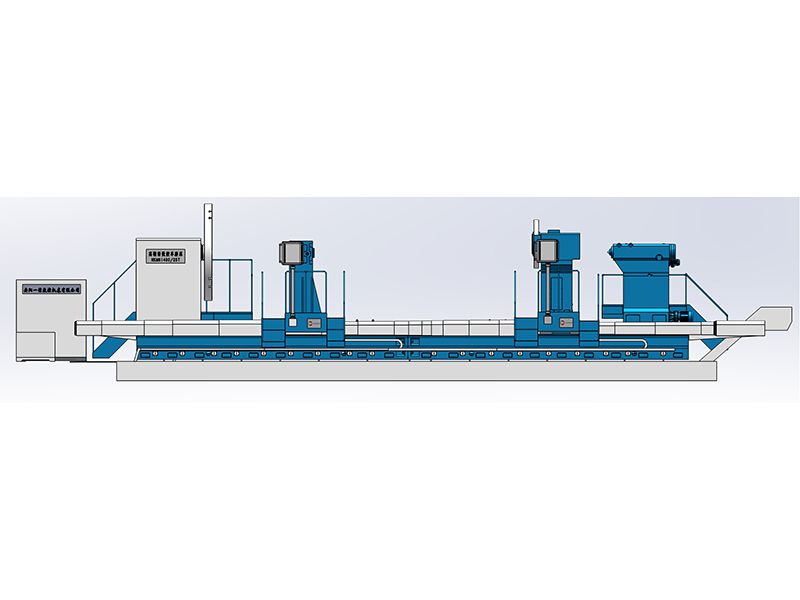

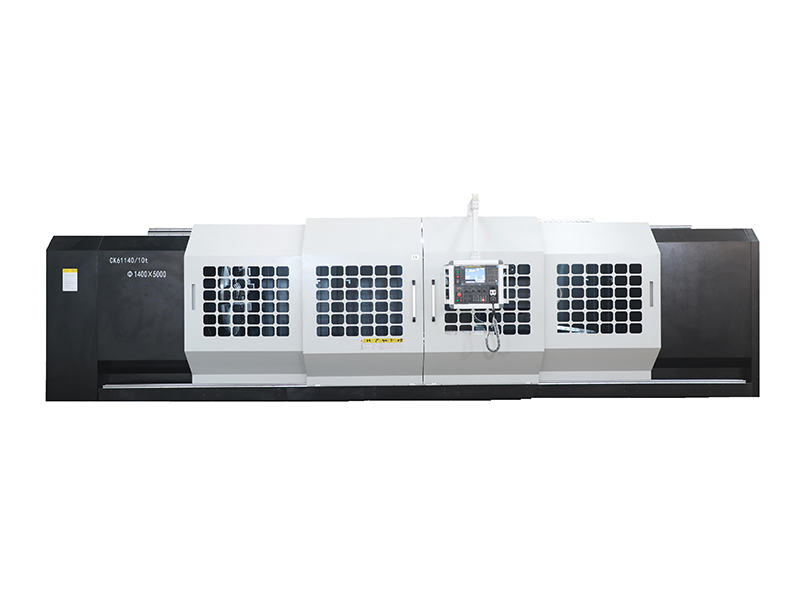

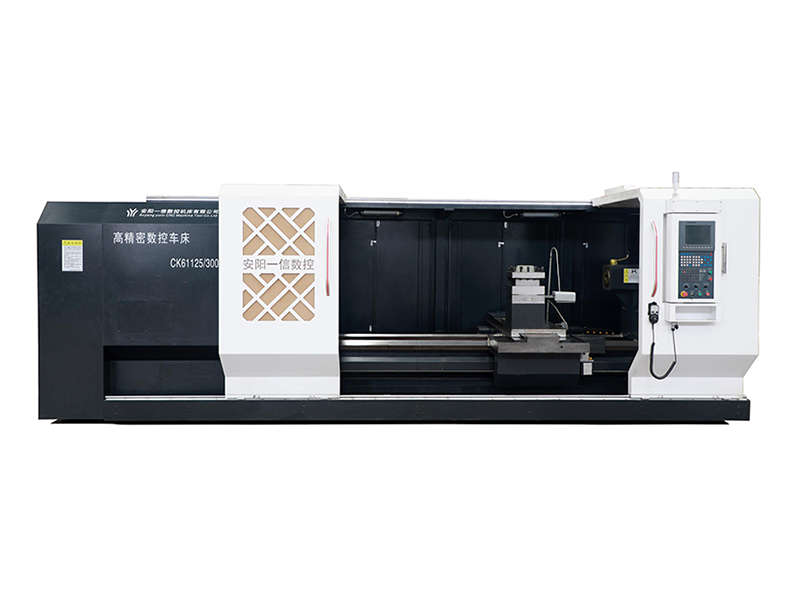

The machine tool combines the advanced features of high-precision CNC lathes at home and abroad, pursues high stability, high speed and high efficiency, conducts finite element analysis on the machine bed, saddle, spindle box, etc., integrates high-speed spindle technology, dynamic servo drive technology, machine tool thermal deformation control and compensation technology, machine tool reliability technology, etc. to design and produce a high-speed and high-efficiency full-type CNC lathe.

This machine tool is a heavy-duty CNC lathe with a semi-closed loop control system, suitable for processing various complex-shaped shafts, sleeves, and disc parts, such as turning inner and outer cylindrical surfaces, conical surfaces, arc surfaces, end faces, grooving, chamfering, threading, etc.

It can be equipped with full chipguard ,chip conveyor, other type turret ,steady rest, follow rest, bracket, electric box air conditioner, etc.; other CNC systems can also be selected.

Product features:

The system is equipped with Siemens system as standard.

The guide rail is a "one mountain and one flat" structure with a guide rail span of 755mm.

The spindle box adopts a precision spindle, and is equipped with P4-level high-precision high-speed spindle bearings as standard.

High efficiency and low noise design, the machine tool speed change system adopts hydraulic automatic two-speed speed change; the low-speed gear achieves low-speed and high-torque output, and realizes heavy cutting; the high-speed gear achieves constant linear speed and high-speed precision cutting, and realizes some parts by turning instead of grinding, and the roughness reaches 0.8.

The feed system adopts a new bearing support structure, standard high-precision and high-load precision ball screw, Z-axis is equipped with a precision 3-arc planetary reducer, German KTR coupling and Taiwan Yingxi high-precision and high-load locking nut.

The machine tool adopts an integral casting bed, the guide surface is quenched and ground, with good rigidity and shock absorption, which can ensure high-precision cutting.

The machine tool protection is novel and atmospheric, the layout of the electric box is reasonable, the operation and maintenance are convenient, and the degree of humanization is high.

| Item | Unit | CK61100 | CK61125 | CK61160 | |

| Capacities | Swingoverbed | mm | 1000 | 1250 | 1640 |

| Swingovercarriage | mm | 630 | 880 | 1250 | |

| Max.lengthofworkpiece | mm | 1500/3000/5000 | |||

| Max.tuininglength | mm | 1300/2800/4800 | |||

| Panofguideway | mm | 755 | |||

| Max.weightofworkpiece | t | 6 | |||

| Spindle | Spindlebore | mm | 130 | ||

| Taperholeofspindle | Metric 140 | ||||

| Chuck | mm | Four Claw Single Action 1000 | |||

| Spindlenose | A215(1:4;φ285.775mm) | ||||

| No.ofspindlespeeds | Two speed stepless | ||||

| Rangeofspindlespeeds | r/min | 5~320 | |||

| feed | Rapidspeeds | m/min | May 5th | ||

| Max.travel | mm | 520 | 700 | ||

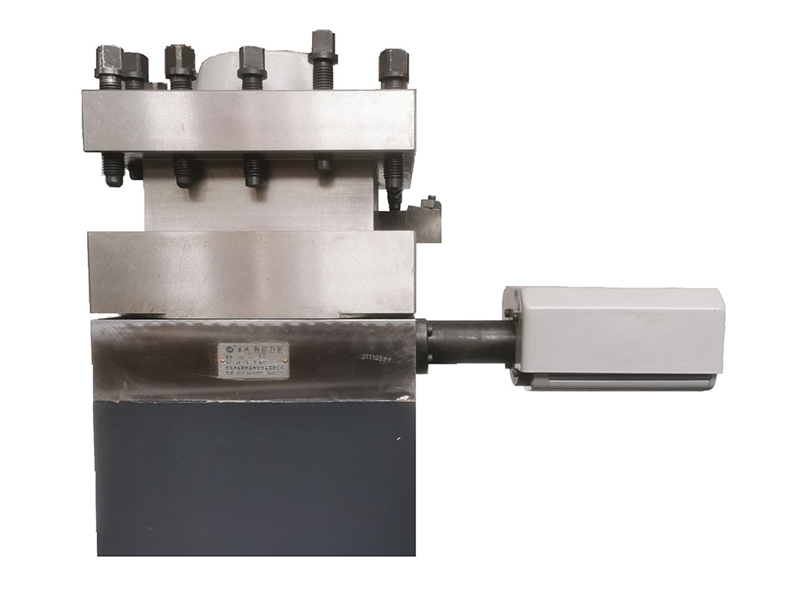

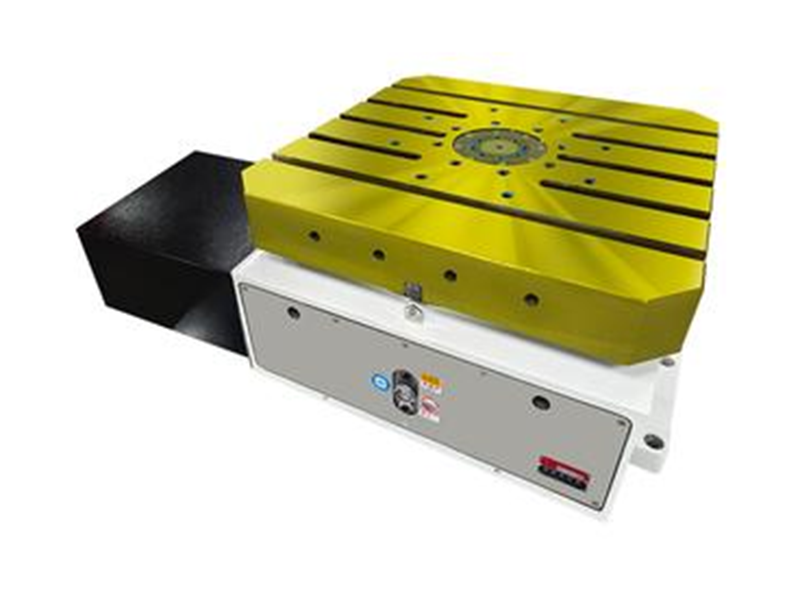

| Tool post & Tails tock | Sizeofturret | mm | 300×300 | ||

| Sectionoftoolshank | mm | 40×40 | |||

| Turretworkingposition | mm | 4 | |||

| Dia.oftailstockquill | mm | 160 | |||

| Travaloftailstockquill | mm | 300 | |||

| Taperholeoftailstock | mm | Mo's No. 6 | |||

| Others | Workpieceaccuracy | It7 | |||

| Surfaceroughness | μm | Ra1.6 | |||

| Mainpower | kW | 30 | |||

| Length | mm | 4800/6300/8300 | |||

| Width/Height | mm | 2300/2300(CK61125) | |||

| Lathemass | t | CK61125:10.2/11.8/14.8 | |||

| CNCSystem | Taiwan's new generation 21TA-E (can be customized according to requirements) | ||||