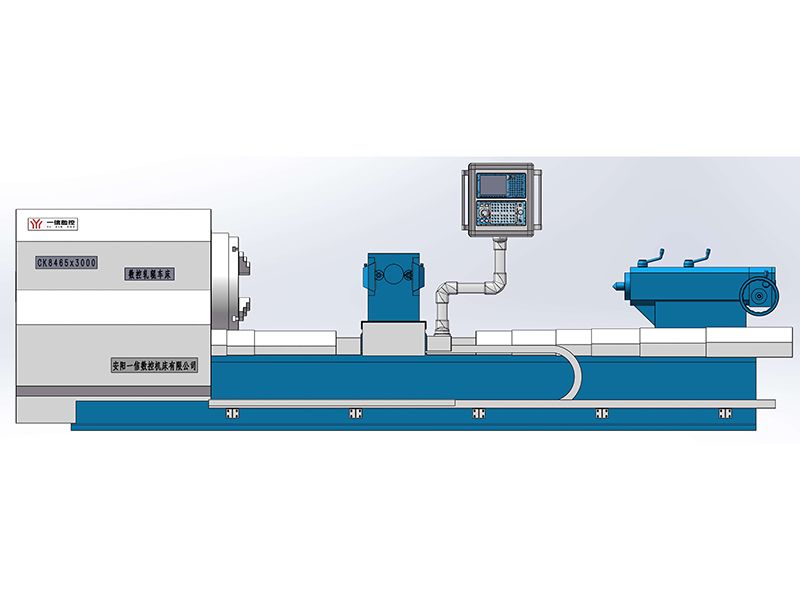

The CK8450 series heavy-duty CNC rolling mill lathe is a high-precision large-scale CNC rolling mill lathe designed and produced by combining advanced processing technology for complex heavy-duty shaft and disc parts, advanced technology for heavy-duty CNC rolling mill lathes and high-precision CNC lathes at home and abroad, with the goal of pursuing high speed, high precision, and high efficiency. It uses finite element analysis and other methods to analyze and research high-speed, precision, heavy-duty spindle design and manufacturing technology, high-power C-axis design technology, precision feed drive technology, precision quick change device technology, CNC servo parameter optimization technology, thermal deformation control and compensation technology, reliability technology, etc. Mainly suitable for high-speed steel, tungsten carbide or hard alloy cutting tools for processing cylindrical surfaces, outer curved surfaces and various rolling rolls of cast iron, steel and non-ferrous metal parts. It can also be used for batch processing of internal and external circles, conical surfaces, end faces and threads of various workpieces such as shafts and disks. High efficiency, simple operation, safe and reliable. Widely used in high-precision machining in industries such as steel, coal mining, mining, wind power, automotive, petroleum, and military. The heavy-duty CNC rolling mill lathe is a high-precision large-scale CNC rolling mill lathe designed and produced by combining the advanced processing technology of complex heavy-duty shaft and disc parts, as well as the advanced technology of heavy-duty CNC rolling mill lathes and high-precision CNC lathes at home and abroad, with the goal of pursuing high speed, high precision, and high efficiency. It uses finite element analysis and other methods to analyze and research high-speed, precision, heavy-duty spindle design and manufacturing technology, high-power C-axis design technology, precision feed drive technology, precision quick change device technology, CNC servo parameter optimization technology, thermal deformation control and compensation technology, reliability technology, etc. Mainly suitable for high-speed steel, tungsten carbide or hard alloy cutting tools for processing cylindrical surfaces, outer curved surfaces and various rolling rolls of cast iron, steel and non-ferrous metal parts. It can also be used for batch processing of internal and external circles, conical surfaces, end faces and threads of various workpieces such as shafts and disks. High efficiency, simple operation, safe and reliable. Widely used in high-precision machining in industries such as steel, coal mining, mining, wind power, automotive, petroleum, and military.Product features:The standard configuration of the system is Siemens 828D system, which can be optionally equipped with other domestic or imported systems.The machine tool adopts a four rail structure, with the main and auxiliary rails separated. The machine tool rail has a large span, can withstand large loads, has high rigidity, good precision, and is easy to maintain in the future.Adopting a heavy-duty built-in rotating tailstock, the tailstock sleeve has a large diameter, a sturdy structure, and can withstand heavy cutting.The spindle unit adopts hydraulic two speed variable speed, with a large spindle diameter and three-point support by precision heavy-duty bearings. The bearing accuracy adopts P4 level; The spindle motor adopts AC servo spindle motor, with low rated speed, high torque and moment of inertia; Combined with low-speed gear, it is suitable for rough machining of heavy parts. Combined with high-speed gear, it can improve the surface machining accuracy of parts and is suitable for precision machining, achieving the replacement of grinding with turning for some parts.Modular design of machine tools allows for functional expansion. By using a quick change device and adding grinding heads, it can be expanded into an external cylindrical grinder; Equipped with a power tool holder, it can be expanded into a turning and milling composite center;Mechanical arms can be added.The machine tool electrical box is equipped with air conditioning as standard, and all main electrical control components are made of Schneider products from Germany, with low failure rate and maintenance costs, ensuring efficient machining of the machine tool.Machine tool protection can be configured according to user needs, including simple protection, double door protection, full protection, etc;According to the requirements of the user for processing parts, chip conveyors, cooling water tanks, etc. can be configured.ItemUnitCK8450CK8465CK8480CapacitiesSwing over carriagemm500650800Max.length of workpiecemm25003000 - 10000Max.tuininglengthmm25003000 - 10000Pan of guidewaymm1000Max.weight of workpiecet3t6t8tSpindleSpindle boremm100Taper hole of spindleMetric 105Metric 140Metric 140Chuckmmfour claws Φ 500four claws Φ 630four claws Φ800Spindle noseA2-11A2-15A2-15Range of spindle speedsr/min5 ~5005 ~3005 ~300No.of spindle speedsHydraulic two gearsFeedRapid speedsm/min10/10Max.travelmm450Tool post& TailstockSize of turretmm280×280300×300300×300Section of tool shankmm40×4040×4040×40Turret working positionmm4Dia.of tailstock quillmm200200220Traval of tailstock quillmm300Taperhole of tailstockmmMT-6OthersWorkpiece accuracyIt7Surface roughnessμmRa0.8Main powerkW223045Width/Heightmm2500/1800CNC SystemStandard configuration: Siemens 828D from Germany (can be customized according to requirements)

Consultation

Consultation

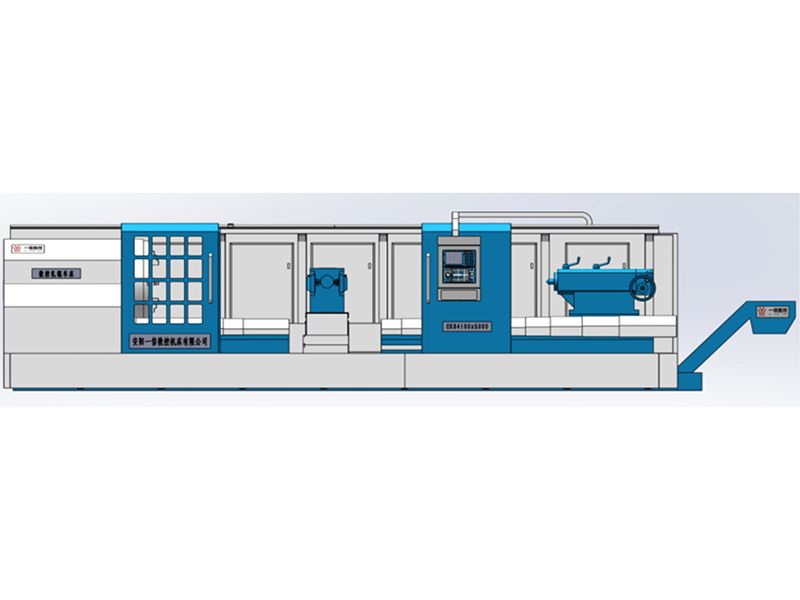

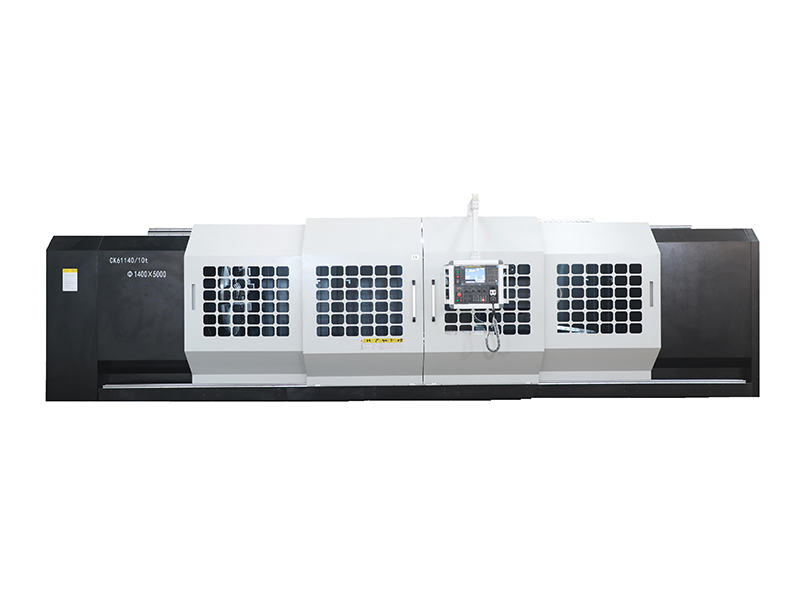

Product features:The standard configuration of the system is the Siemens 828D system from Germany.The machine tool bed adopts a four rail, linear rail, and rectangular composite structure. The main and auxiliary rails are separated, and the machine tool rails have a large span. The Z-direction feed system adopts heavy-duty linear roller rails and applies heavy-duty pre tensioning, which can withstand large loads, have high rigidity, and good precision.The machine tool is equipped with a heavy-duty built-in rotating tailstock, with a large tailstock sleeve diameter and a stroke of 300mm. The top is MT-6, which has a sturdy structure and can withstand heavy cutting.The spindle unit adopts hydraulic two speed variable speed, with a large spindle diameter and three-point support by precision heavy-duty bearings. The bearing accuracy adopts P4 level; The spindle motor adopts AC servo spindle motor, with low rated speed, high torque and moment of inertia; Combined with low-speed gear, it is suitable for rough machining of heavy parts. Combined with high-speed gear, it can improve the surface machining accuracy of parts and is suitable for precision machining, achieving the replacement of grinding with turning for some parts.Modular design of machine tools allows for functional expansion. By using a quick change device and adding grinding heads, it can be expanded into an external cylindrical grinder; Equipped with a power tool holder, it can be expanded into a turning and milling composite center;Mechanical arms can be added.The machine tool electrical box is equipped with air conditioning as standard, and all main electrical control components are made of Schneider products from Germany, with low failure rate and maintenance costs, ensuring efficient machining of the machine tool.Machine tool protection can be configured according to user needs, including simple protection, double door protection, full protection, etc;According to the requirements of the user for processing parts, chip conveyors, cooling water tanks, etc. can be configured.ItemUnitCK8480CK84100CK84125CapacitiesSwing over carriagemm80010001250Max.length of workpiecemm3000 - 10000Max.tuininglengthmm3000 - 10000Pan of guidewaymm1250Max.weight of workpiecet10t12t12tSpindleSpindle boremm100Taper hole of spindleMetric 140Chuckmmfour claws 800four claws 1000four claws 1000Spindle noseA2-15No.of spindle speedsHydraulic two gearsRange of spindle speedsr/min5 ~300FeedRapid speedsm/min10/6Max.travelmm500Max.travelmm3000-10000Tool post& TailstockSize of turretmm300×300350×350380×380Section of tool shankmm40×4050×5050×50Turret working positionmm4Dia.of tailstock quillmm220260260Traval of tailstock quillmm300Taperhole of tailstockmmMT-6OthersWorkpiece accuracyIt7Surface roughnessμmRa 0.8Main powerkW455555Width/Heightmm2900/1900(Simple protection)3100/2300(Double door protection)CNC SystemSiemens Germany 828D(Customizable according to requirements)

Consultation

Consultation

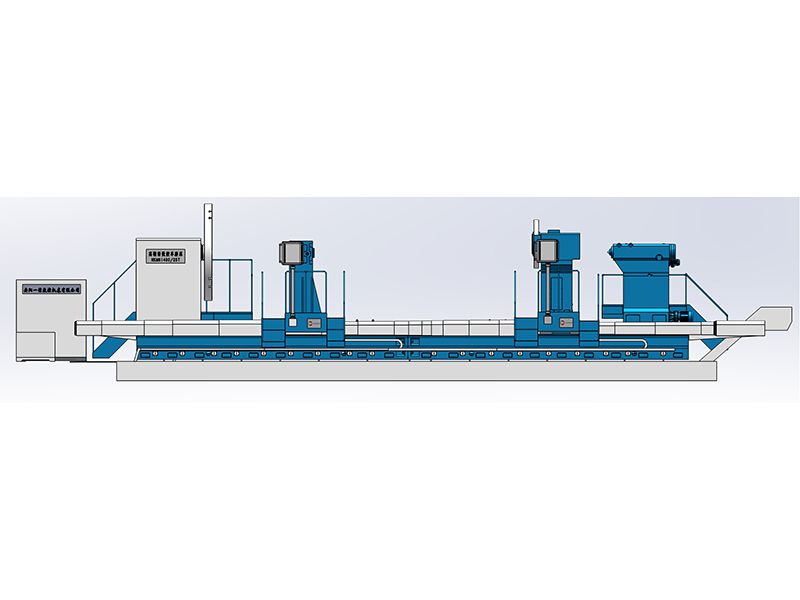

The heavy-duty CNC lathe grinder is a heavy-duty CNC lathe grinder designed and produced by our company based on the current processing technology of medium and large parts, combined with advanced technologies of heavy-duty CNC roll lathes and CNC roll grinders at home and abroad, with the goal of pursuing safety, reliability, and cost savings. Using modern CNC machine tool design methods as a means, we analyze and research high-speed precision spindle design and manufacturing technology, precision feed drive technology, CNC servo parameter optimization technology, thermal deformation control and compensation technology, reliability technology, etc.This equipment is mainly used for processing shaft and roll parts in plastic machinery, steel rolling, papermaking machinery, and other special industries. It is suitable for cutting tools such as high-speed steel, hard alloy, cubic boron nitride, diamond, etc. It is suitable for rough and fine machining of black metal, non-ferrous metal, and some non-metallic parts. It can turn the cylindrical surface, conical surface, end surface, groove, and circular arc surface of the parts, and grind the outer circle of rotary parts.Product features:The standard configuration of the system is Siemens 828D from Germany, with dual operation boxes and dual screen displays.The machine tool bed adopts a double bed structure, with a large span for a single bed and a span of 4020mm for two beds. It can withstand large loads, has high rigidity, and good precision.The machine tool is equipped with a heavy-duty built-in rotating tailstock, with a large tailstock sleeve diameter, a stroke of 300mm, and a top taper of metric 100. The structure is sturdy and can withstand heavy cutting.The machine tool spindle adopts hydraulic two speed variable speed, with a large spindle diameter and three-point support by precision heavy-duty bearings. The bearing accuracy adopts P4 level;The spindle motor adopts Siemens 95Kw AC servo spindle motor from Germany, which has high torque and moment of inertia;When paired with low-speed gear, it is suitable for rough machining of heavy parts. When paired with high-speed gear, it can improve the surface machining accuracy of parts and is suitable for precision machining.The machine tool adopts a dual tool holder structure, one for turning and the other for grinding. The grinding tool holder spindle adopts a static pressure spindle, which has good rigidity and high rotation accuracy, suitable for precision grinding processing.The machine tool electrical box is equipped with air conditioning as standard, and all main electrical control components are made of Schneider products from Germany, with low failure rate and maintenance costs, ensuring efficient machining of the machine tool.Modular design of machine tools allows for functional expansion. By using a quick change device and equipped with a power tool holder, it can be expanded into a turning and milling composite center; Mechanical arms can be added.ItemUnitHKM61400/25CapacitiesSwing over bedmm4000Swing over carriagemm3500Max.length of workpiecemm10000Max.weight of workpiecet25Taper hole of spindle公制140Chuckmm四爪2500Spindle noseA2-15No.of spindle speeds液压两挡Range of spindle speedsr/min1 ~100FeedRapid speedsm/min10/5Max.travelmm10000Max.travelmm1200Tool post& TailstockSize of turretmm框式刀架Section of tool shankmm70 ×60Turret working positionmm2Dia.of tailstock quillmm300Traval of tailstock quillmm300Taperhole of tailstockmm公制 100OthersMain powerkW210Lengthmm21000Width/Heightmm7400/4300CNC System西门子828D(可根据要求定制)

Consultation

Consultation

CXK350 series CNC screw milling machine CXK350 series irregular CNC screw milling machine is a specialized machine designed for processing various irregular screws such as equal lead, variable lead, gradient lead, equal groove depth, and variable groove depth. This product aims to pursue high speed, high precision, and high efficiency, and uses finite element analysis and other methods to analyze, research, design, and produce special-shaped CNC screw milling machines based on high-speed, precision, heavy-duty spindle design and manufacturing technology, high-power C-axis design technology, precision feed drive technology, CNC servo parameter optimization technology, thermal deformation control and compensation technology, reliability technology, etc. It can be processed individually or in batches. High efficiency, simple operation, safe and reliable.Product features:The standard configuration of the system is the Wide Number 980TDI system, and other systems can also be configured according to user needs.The guide rail adopts a "one mountain, one flat" structure, with a large span and good rigidity.The milling spindle adopts an AC servo spindle motor, which can enable the milling cutter to achieve infinite speed and a wide speed range. The milling head can manually adjust the angle according to the requirements of the workpiece.It can achieve multi axis linkage machining, and can complete multiple processes of the screw with one clamping. It can change the lead and diameter, reduce auxiliary time, and greatly improve machining efficiency compared to traditional screw milling machines.According to the shape and processing requirements of the screw, cutting parameters and processing paths can be automatically optimized to increase cutting speed and feed rate, and shorten processing time.The feed system of the machine tool adopts a high rigidity bearing support structure, equipped with high-precision high load ball screws, and the Z-axis is equipped with a precision 3-arc planetary gearbox, German Kaitian coupling, and Taiwan Yingxi high-precision high load locking nut to ensure the accuracy and stability of the machine tool.The machine tool adopts an integral cast bed body, and the guide rail surface is quenched and ground, which has good rigidity and shock absorption, ensuring high-precision cutting processing.The machine tool adopts a simple protective design, novel and atmospheric, reasonable electrical box layout, convenient operation and maintenance, and high degree of humanization.The machine tool electrical box is equipped with air conditioning as standard, and the main electrical control components are all domestic and foreign famous brand products, with low failure rate and low maintenance cost, ensuring efficient machining of the machine tool.MODELCXK350Two top workpiece length2000,3000,4000,5000,6000Maximum machining length of the machine tool1700,2700,3700,4700.5700Maximum machining diameterΦ50-350Bed width755Machine tool center high500Spindle speeds0.1-9(无级)Spindle holeΦ100Type of milling cutterBT50Milling speed ratio1:4The milling head can adjust the angle±30°Miling header spindle speeds50-1000r/minMotor Power of milling header11kWC-axis servo-motor torque22C speed of spindle0-5r/minC axis positioning accuracy10角秒X-axis servo-motor torque22X axis fast shift speed10Z-axis servo-motor torque28Z axis fast shift speed8Tail seat sleeve diameter100Top taper of the seat sleeveMT-5Maximum stroke of sleeve250Card plate specificationsK11-400CNumerical control system广数 980TDIAxisX、Z、C

Consultation

Consultation

This series of machining centers are small and medium-sized machine tools. After one clamping, the workpiece can automatically and continuously complete multiple processes such as milling, drilling, boring, expanding, reaming, countersinking, and tapping. The machine tool is suitable for multi-variety small and medium-sized batch processing of complex parts such as small and medium-sized boxes, plates, discs, valves, shells, molds, etc. It is widely used in precision parts, 5G products, hardware, auto parts, and medical equipment industries. The machining center is easy to clamp, has strong process adaptability, high processing efficiency, low scrap rate, good finished product consistency, and can reduce the requirements for workers' technical proficiency.Product features:l The system is equipped with Huazhong CNC system 808DiM and 10.4-inch color display.l The three-axis guide rail and lead screw protection cover is a fully enclosed protection, which effectively protects the guide rail and lead screw and reduces the damage caused by iron chips, oil stains, dust and cutting fluid.l The integrated box structure design of the saddle significantly improves its support rigidity.l The base is designed with transfer support feet, which is convenient for forklift transportation.l The base bears the cutting force in the spindle direction. In order to reduce the support span of the front and rear feet and enhance the rigidity of the base support, the foot support is added between the front and rear feet to reduce the deformation of the base.l The machine tool is equipped with a standard hat-shaped tool magazine, which is convenient for tool change. Other types of tool magazines can also be configured according to user needs.l The machine tool is equipped with Taiwan University and Okada high-speed spindle units with high rotation accuracy and fast speed.lThe machine tool guide rail adopts a two-wire and one-hard structure, with high fast moving speed, good machine tool rigidity, high precision stability, and is suitable for the processing of rough and fine parts.lThe machine tool coupling adopts German Kaitian or Japanese Miki to ensure the transmission accuracy of the three axes.lThe machine tool electrical box is equipped with air conditioning as standard, and the low-voltage electrical components are produced by Schneider of Germany, with low failure rate and maintenance-free.lThe machine tool has a full protection design, which is novel and atmospheric, easy to operate and maintain the machine tool, the electrical box layout is reasonable, the operation and maintenance are convenient, and the degree of humanization is high.SpecificationunitVMCL850VMCL970VMCL1580X/Y/Z axis travelmm800/500/5001100/650/7501500/800/800Distance from spindle nose to worktablemm110—61095—84585—885Distance from spindle center to column surfacemm560700865Spindle speedrpmbelt 8000belt 8000belt 8000Spindle nose taperBT40/150BT40/150BT50/155Tool change timesecond224Number of cutting toolspc162024Maximum tool weightkg777Spindle motor powerkw7.5/117.5/1115X/Y/Z motor torqueN.m2010/12/1220/20/2028/28/28Table sizemm1000×5001200×6501700×810Maximum load capacity of workbenchkg5008001500T-shaped groove (groove, width, center distance)mm5×18×905×18×1205×18×147.5X-axis rapid displacementm/min242424Y-axis rapid displacementm/min242424Z-axis rapid displacementm/min181614positioning accuracy mm±0.016±0.016±0.016repeatabilitymm±0.008±0.008±0.01Numerical Control SystemHuazhong CNCHuazhong CNCHuazhong CNCmachine weightkg500052008500power requirementkva202535Water tank capacityl250250250Air pressure sourcekg/cm2666

Consultation

Consultation

The main structure of the machine tool is an inverted T-shaped, movable column structure. The machine bed has a large span design, high rigidity and high strength. It can be clamped once to perform milling, drilling, reaming, boring, reaming, tapping and other processes on four surfaces. Modern machine tools and control concepts, compact structural design, ensure high efficiency and high precision processing requirements for single or small and medium batch products. It is suitable for complex processing of box parts.Product features:The system is equipped with Huazhong CNC 808DiM and 10.4-inch color display.The spindle box adopts Taiwan Okada precision high-rigidity spindle unit with a rotation accuracy of 0.002mm, and the bearing adopts precision spindle bearings imported from Japan.The turntable adopts a horizontal three-piece gear-type one-degree-one-minute precision turntable produced in Taiwan, with a table size of 1600×1600, rotation without lifting, and repeated positioning accuracy of 0.001mm.The feed system adopts a new bearing support structure, standard Japanese THK high-precision large-load precision ball screw, accuracy level C3, X/Y axis adds precision 3 arc-minute planetary reducer, German KTR coupling and Taiwan Yingxi high-precision large-load locking nut to ensure high positioning accuracy and repeated positioning accuracy of the machine tool.The machine tool adopts an integral casting bed, large span, wide guide rail, guide rail surface quenching and grinding, with good rigidity and shock absorption, which can ensure high-precision cutting processing. Equipped with Taiwan Okada 30-knife horizontal disc tool magazine, cylindrical cam segmentation structure, high precision and low failure rate; double-bearing separate tool arm, high concentricity, low tool change noise, electronic switch uses imported original parts, reliable quality and long service life. The maximum tool weight is 18kg, and the tool change time is 4.01 seconds.The machine tool has a full protection design, which is novel and atmospheric. The chip conveyor adopts 4 screws and one chain, which is convenient for machine tool operation and maintenance. The layout of the electric box is reasonable, the operation and maintenance are convenient, and the degree of humanization is high.SpecificationunitTH1600feedThree axis travel(X/Y/Z)mm2000×2000×1900Spindle end face to worktable center (front and rear)mm450-2400Spindle center to worktable (up and down)mm100-2000X/Y/Z-axis ball screw specificationsmm80/80/80X/Y/Z axis guide rail typeSliding guide rail, surface quenchedX/Y/Z/W axis feed motor torqueN.m48/48/48/35workbenchTable sizemm1600×1600Maximum load capacity of workbenchKg10000T-shaped groove (groove x width x center distance)mm7×22×200Dividing angle°1°principal axisMain spindle formmmØ190-BT50Spindle motor powerKw21Rated speed of spindle motorr/min1000Spindle speedr/min5-6000Spindle motor torqueN.m200Knife storageNumber of knives allowedT30Maximum tool diametermmØ125Neighbor Empty KnifemmØ200Maximum tool lengthmm400Maximum allowable weight of cutting toolsKg18Tool change timesec4speedFast moving speed(X/Y/Z)m/min10feed rate(X/Y/Z)mm/min1-5000Workbench speedr.p.m3accuracypositioning accuracymm±0.025Repetitive positioning accuracymm0.016otherTotal capacity of machine tool power supplykw65

Consultation

Consultation

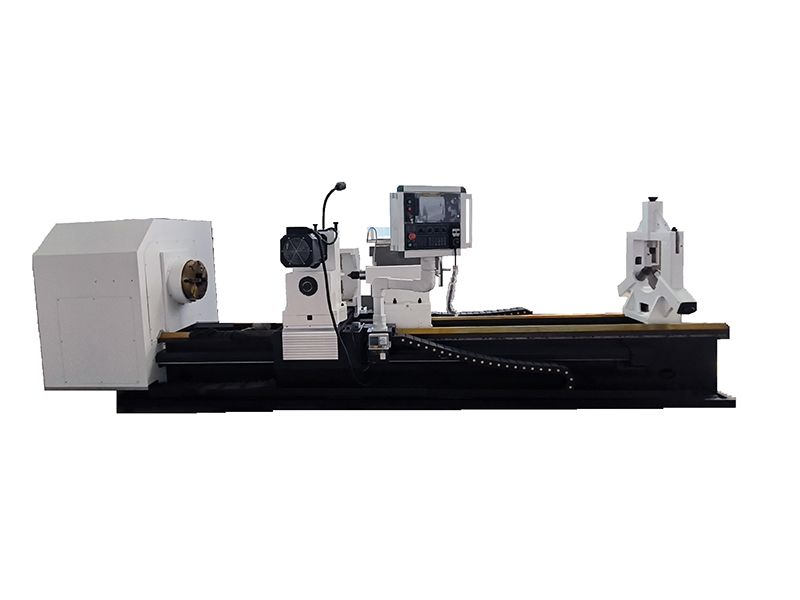

This machine tool is a heavy-duty semi-closed-loop controlled CNC lathe developed according to the special needs of users and the difficulties in user processing. The machine tool adopts open protection, and it is convenient and quick to clamp parts. It is suitable for processing various complex-shaped shafts, sleeves, and disc parts, such as turning internal and external cylindrical surfaces, conical surfaces, arc surfaces, end faces, grooving, chamfering, and threading.The power turret can be optionally upgraded to a turning and milling center to adapt to the processing of various complex parts. It can also be equipped with a steady rest, a bracket, etc.; and other CNC systems can be selected.Product features:The system is equipped with Siemens system as standard.The guide rail is a "one mountain and one flat" structure, and the guide rail span is 1100mm.The heavy-duty built-in rotary tailstock has a tailstock sleeve diameter of Φ260mm and a stroke of 300mm.The spindle box adopts a precision spindle and is equipped with P4-level high-precision high-speed spindle bearings as standard.The machine tool speed change system adopts hydraulic automatic two-speed speed change; the low-speed gear achieves low-speed and high-torque output to achieve heavy cutting; the high-speed gear achieves constant linear speed and high-speed precision cutting, and some parts are replaced by turning instead of grinding, with a roughness of 0.8.The feed system adopts a new bearing support structure, with high-precision and high-load precision ball screws as standard, and the Z-axis is equipped with a precision 3-arc-minute planetary reducer, a German KTR coupling and a Taiwan Yingxi high-precision and high-load locking nut.The machine tool adopts an integral casting bed, and the guide surface is quenched and ground. It has good rigidity and shock absorption, which can ensure high-precision cutting.The machine tool adopts simple protection, novel and elegant, reasonable layout of the electrical box, convenient operation and maintenance, and high degree of user-friendliness.ItemUnitCK61160CK61180CK61200CapacitiesSwingoverbedmm160018002000Swingovercarriagemm120014001600Max.lengthofworkpiecemm2000/3000/5000/6000Max.tuininglengthmm1800/2800/4800/5800Panofguidewaymm1100Max.weightofworkpiecet16SpindleSpindleboremm100TaperholeofspindleMetric 140ChuckmmFour Claws 1250SpindlenoseA215(1:4;φ285.775mm)No.ofspindlespeedsTwo speed steplessRangeofspindlespeedsr/min5~320feedRapidspeedsm/minMay 5thMax.travelmm850Tool post&Tails tockSizeofturretmm380×380Sectionoftoolshankmm50×50Turretworkingpositionmm4Dia.oftailstockquillmm260Travaloftailstockquillmm300Taperholeoftailstockmm公制80#OthersWorkpieceaccuracyIt7SurfaceroughnessμmRa1.6MainpowerkW45Lengthmm5300/6300/8300/9300Width/Heightmm3100/2700(CK61160)CNCSystemTaiwan's new generation 21TA-E (can be customized according to requirements)

Consultation

Consultation

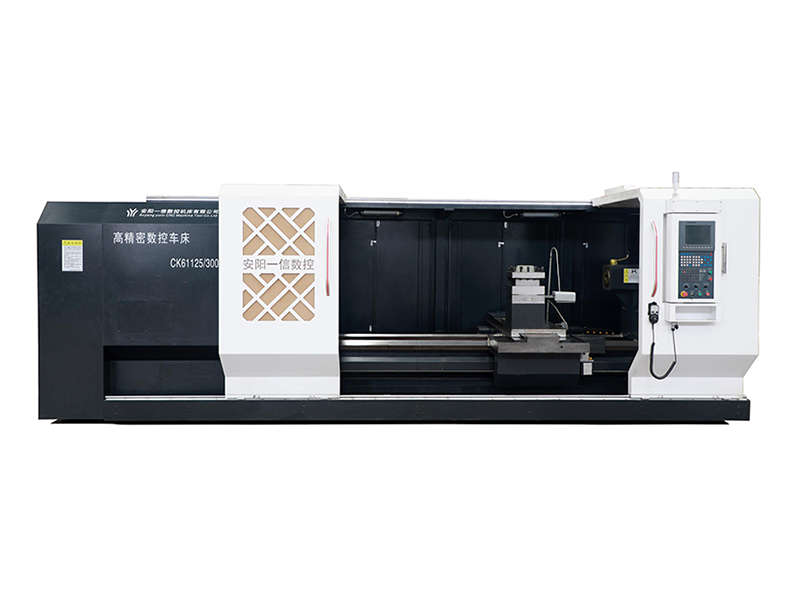

The system is equipped with Siemens system as standard.The guide rail is a "one mountain and one flat" structure with a guide rail span of 1000mm.The spindle box adopts a precision spindle, and is equipped with P4-level high-precision high-speed spindle bearings as standard.High efficiency and low noise design, the machine tool speed change system adopts hydraulic automatic two-speed speed change; the low-speed gear achieves low-speed and high-torque output, and realizes heavy cutting; the high-speed gear achieves constant linear speed and high-speed precision cutting, and realizes some parts by turning instead of grinding, and the roughness reaches 0.8.The feed system adopts a new bearing support structure, standard high-precision and high-load precision ball screw, Z-axis is equipped with a precision 3-arc planetary reducer, German KTR coupling and Taiwan Yingxi high-precision and high-load locking nut.The machine tool adopts an integral casting bed, the guide surface is quenched and ground, with good rigidity and shock absorption, which can ensure high-precision cutting.The machine tool protection is novel and atmospheric, the layout of the electric box is reasonable, the operation and maintenance are convenient, and the degree of humanization is highItemUnitCK61125CK61140CK61160CapacitiesSwingoverbedmm125014001600Swingovercarriagemm88010101210Max.lengthofworkpiecemm1500/3000/5000Max.tuininglengthmm1300/2800/4800Panofguidewaymm1000Max.weightofworkpiecet10SpindleSpindleboremm130TaperholeofspindleMetric 140ChuckmmFour Claw Single Action 1250SpindlenoseA215(1:4;φ285.775mm)No.ofspindlespeedsTwo speed steplessRangeofspindlespeedsr/min5~320feedRapidspeedsm/minMay 5thMax.travelmm700Tool post&Tails tockSizeofturretmm350×350Sectionoftoolshankmm40×40Turretworkingpositionmm4Dia.oftailstockquillmm220Travaloftailstockquillmm300TaperholeoftailstockmmMo's No. 6OthersWorkpieceaccuracyIt7SurfaceroughnessμmRa1.6MainpowerkW45Lengthmm5000/6500/8500Width/Heightmm3000/2600(CK61140)LathemasstCK61125:12/14/17CNCSystemTaiwan's new generation 21TA-E(can be customized according to requirements)

Consultation

Consultation

The machine tool combines the advanced features of high-precision CNC lathes at home and abroad, pursues high stability, high speed and high efficiency, conducts finite element analysis on the machine bed, saddle, spindle box, etc., integrates high-speed spindle technology, dynamic servo drive technology, machine tool thermal deformation control and compensation technology, machine tool reliability technology, etc. to design and produce a high-speed and high-efficiency full-type CNC lathe.This machine tool is a heavy-duty CNC lathe with a semi-closed loop control system, suitable for processing various complex-shaped shafts, sleeves, and disc parts, such as turning inner and outer cylindrical surfaces, conical surfaces, arc surfaces, end faces, grooving, chamfering, threading, etc.It can be equipped with full chipguard ,chip conveyor, other type turret ,steady rest, follow rest, bracket, electric box air conditioner, etc.; other CNC systems can also be selected.Product features:The system is equipped with Siemens system as standard.The guide rail is a "one mountain and one flat" structure with a guide rail span of 755mm.The spindle box adopts a precision spindle, and is equipped with P4-level high-precision high-speed spindle bearings as standard.High efficiency and low noise design, the machine tool speed change system adopts hydraulic automatic two-speed speed change; the low-speed gear achieves low-speed and high-torque output, and realizes heavy cutting; the high-speed gear achieves constant linear speed and high-speed precision cutting, and realizes some parts by turning instead of grinding, and the roughness reaches 0.8.The feed system adopts a new bearing support structure, standard high-precision and high-load precision ball screw, Z-axis is equipped with a precision 3-arc planetary reducer, German KTR coupling and Taiwan Yingxi high-precision and high-load locking nut.The machine tool adopts an integral casting bed, the guide surface is quenched and ground, with good rigidity and shock absorption, which can ensure high-precision cutting.The machine tool protection is novel and atmospheric, the layout of the electric box is reasonable, the operation and maintenance are convenient, and the degree of humanization is high.ItemUnitCK61100CK61125CK61160CapacitiesSwingoverbedmm100012501640Swingovercarriagemm6308801250Max.lengthofworkpiecemm1500/3000/5000Max.tuininglengthmm1300/2800/4800Panofguidewaymm755Max.weightofworkpiecet6SpindleSpindleboremm130TaperholeofspindleMetric 140ChuckmmFour Claw Single Action 1000SpindlenoseA215(1:4;φ285.775mm)No.ofspindlespeedsTwo speed steplessRangeofspindlespeedsr/min5~320feedRapidspeedsm/minMay 5thMax.travelmm520700Tool post&Tails tockSizeofturretmm300×300Sectionoftoolshankmm40×40Turretworkingpositionmm4Dia.oftailstockquillmm160Travaloftailstockquillmm300TaperholeoftailstockmmMo's No. 6OthersWorkpieceaccuracyIt7SurfaceroughnessμmRa1.6MainpowerkW30Lengthmm4800/6300/8300Width/Heightmm2300/2300(CK61125)LathemasstCK61125:10.2/11.8/14.8CNCSystemTaiwan's new generation 21TA-E (can be customized according to requirements)

Consultation

Consultation